In a world where time is of the essence and creativity knows no bounds, rapid prototyping (RP) emerges as a revolutionary force, transforming the product development landscape. Imagine a realm where your brilliant design ideas are no longer confined by the shackles of lengthy development cycles and exorbitant prototyping expenses. RP shatters the conventional boundaries, empowering innovators, entrepreneurs, and businesses alike to materialize their visions with unprecedented speed and efficiency.

From Sketch to Reality in a Flash

Gone are the days of waiting months for a physical prototype. RP employs advanced technologies to compress the prototyping process into a fraction of the time, enabling designers to iterate swiftly and refine their concepts in near real-time. This rapid turnaround time allows for exploring multiple design variations, user testing, and quick adjustments based on feedback, resulting in a streamlined and optimized product development journey.

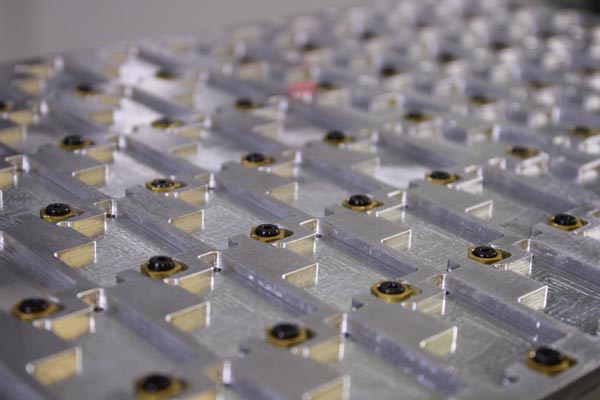

But speed is not the sole advantage of RP. It also significantly reduces the costs associated with traditional prototyping methods. By leveraging cutting-edge manufacturing techniques such as 3D printing, laser cutting, and CNC machining, RP eliminates the need for expensive tooling and large production runs. This cost-effectiveness makes it an accessible option for startups, small businesses, and individual designers who previously might have found traditional prototyping prohibitive.

RP has far-reaching implications for low-volume manufacturing. It enables businesses to produce custom products, spare parts, and small batches in a timely and cost-effective manner. This flexibility paves the way for personalized products, limited editions, and niche markets that would otherwise be economically unviable. RP also empowers manufacturers to respond swiftly to market demands, adjust production volumes based on customer feedback, and minimize the risk of overproduction.

RP is like a fast-forward button for the product creation process. It allows you to take your concept from a napkin sketch to a tangible prototype in a fraction of the time and cost compared to traditional methods. Think 3D printing, CNC machining, and laser cutting, all working their magic to bring your vision to life with lightning speed.

Low volume CNC parts

Why is Rapid Prototyping the MVP (Most Valuable Player) in Low-Volume Manufacturing?

- Speed Demon: Time is money, especially in the world of business. RP slashes the time it takes to create a prototype, allowing you to quickly test, iterate, and refine your design. This accelerates development cycles, gets your product to market faster, and keeps you ahead of the competition.

- Cost-Effective Champion: Gone are the days of breaking the bank just to get a prototype made. RP offers a cost-efficient way to bring your ideas to life. This makes it ideal for startups, independent designers, and businesses with limited budgets.

- Innovation Accelerator: RP empowers you to experiment and push design boundaries without fearing huge financial risks. Before committing to full-scale production, you can test different concepts, iterate on features, and refine your design. This unleashes innovation and allows you to create truly groundbreaking products.

- Feedback Frenzy: RP allows you to get valuable feedback from users early and often. By putting a physical prototype in their hands, you can gather real-world insights, identify usability issues, and make informed design decisions before investing in mass production.

Beyond the Buzzwords: Real-World Examples

RP isn’t just a buzzword; it’s having a real impact on various industries:

- Consumer Electronics: From customizable headphones to innovative smartphone cases, RP allows companies to test different designs and gather user feedback before launching new products.

- Automotive: RP is used to create functional prototypes of car parts, allowing engineers to test functionality and performance before going into production.

- Fashion: Designers use RP to create customizable clothing and unique accessories, offering a more personalized and sustainable approach to fashion.

The Future is Prototyped

The world of RP is constantly evolving, with new technologies and materials always emerging. As RP becomes more accessible and affordable, we expect to see even faster iterations, wider material choices, and even more innovative applications.

So, if you’re looking to revolutionize your product development process and dominate the low-volume manufacturing landscape, embrace rapid prototyping. It’s the fast track to innovation and the key to unlocking your product’s full potential.