NICE Rapid Blog

Latest news and knowledge to share.

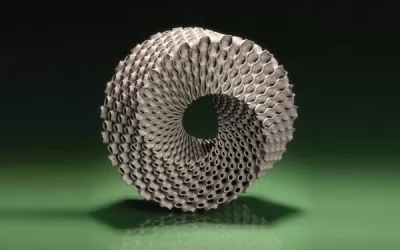

Your Guide to 3D Printing Services

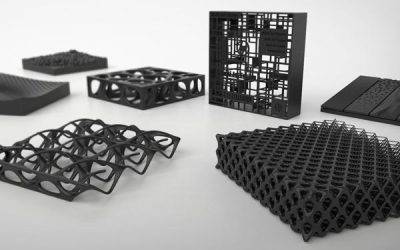

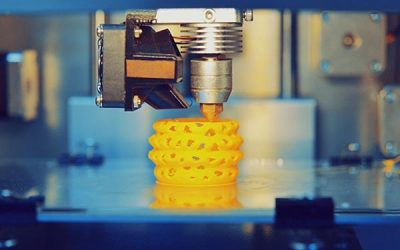

3D printing is amongst the most cutting-edge technology that allows the creation of a physical part/product from a wide range of digital models depending on your printing needs and requirements. In the beginning, the first printing service was introduced in the 1980s...

Benefits of 3D Printing to the Society

3D printing refers to coming up with three-dimensional items from a digital page or picture. This type of printing enables an artist to produce more complex artifacts and make them more visual. Among the essential tools for 3D printing include 3D printers and software...

Liquid Silicone Rubber Molding: Here’s What You Should Know

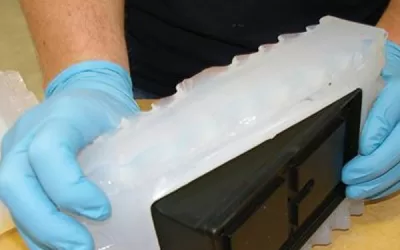

Curious about what liquid silicone rubber molding is all about? You have come to the right page. We are going to talk about this manufacturing process that involves liquid silicone rubber to create pliable and durable parts in large volumes. This silicone rubber...

What Is Silicone Vacuum Casting And How Can It Be Improved?

Developed in two German universities in the 1960s, silicone vacuum casting is a production technique which combines the two methods of duplication with vacuum and moulds of silicone. This duplication technique is widely employed for the manufacture of small batches of...

NICE Rapid Announces ISO 9001 Certification

After one year of preparation, NICE rapid model company, from preparing documents, adjusting management, optimizing processes, to on-site rectification, finally passed the ISO 9001 audit on December 29, 2019. What is ISO 9001? ISO 9001 is transformed from the world's...

What is Known by the Process of Rapid Tooling and its Significant Advantages

Rapid tooling, also known as Rapid prototyping or RP, is defined as the process of making technology a simple solution to create things more smartly. It involves various proceedings for 3D printing options and opportunities that are used for designing and developing...

Why Should You Opt For rapid tooling?

Many sectors such as healthcare, automobiles, and manufacturing require customized parts. These requirements are usually urgent which leaves no scope for trial and error. Time is of the essence in many aspects of life and instead of waiting for a highly accurate...

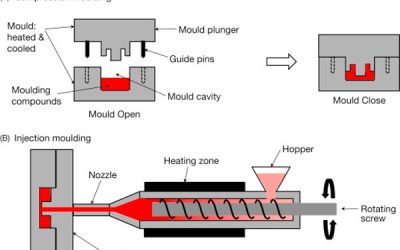

The Benefits and Drawbacks of Using Compression Molding

The process remained unchanged and it involves putting the rubber compound into a mold that takes the shape of the intended product. Its resulting product is slightly larger than what would be its final shape. Compression molding uses pressure and heat to thermoset...

The Advantages of Using 3D Printing for Prototyping

The use of 3D printing is on the rise for a lot of reasons. It can produce tools, toys, and even aircraft parts in a flash without needing for tooling. And it is often referred to as the production method of the future because it can manufacture three-dimensional...

Here’s What You Should Look for In a Prototype Manufacturer

For a design team, having your concept translated into a prototype is the next step to test your idea in the real world. If you are starting to look around for a prototype manufacturer, you need to know a few things about the company. Here are the five things that you...

4 Reasons Why Prototype Manufacturing is Important

Every designer would want a working model for their design to show them to potential stakeholders, but prototype manufacturing does more than that. Creating a prototype is not only critical to the design process but also for the manufacturers to know if they have a...

Everything You Need to Know about CNC Machining

By now you must know that CNC machining is used in industrial and manufacturing application. But what exactly does it imply and what a CNC machining is? We will discuss it in the following passages. So take a look. Computer numerical control is a subtractive...

Prototype and Manufacturing Services Near By

Rapid Prototyping Services

Turn your ideas into reality fast with our rapid prototyping services. From concept to 3D printing, we bring your vision to life quickly and accurately. Stay ahead of the curve and accelerate your product development process with us.

Silicone Molding

Experience seamless production with our silicone molding expertise. Our precise techniques ensure high-quality, custom molds that bring your designs to life with exceptional detail and durability. Whether you’re crafting prototypes or mass-producing products, our silicone molding services offer efficiency and reliability, empowering you to achieve your goals with confidence.