NICE Rapid Blog

Latest news and knowledge to share.

Overmolding with Liquid Silicone Rubber Techniques and Benefits

Liquid silicone rubber molding is a versatile manufacturing process that offers many benefits over traditional injection molding. One of the critical advantages of liquid silicone rubber molding is the ability to overmold parts, adding a layer of functionality and...

Why Do Companies Rely on Silicone Molding Services in China?

China has a growing reputation as a powerhouse of international manufacturing. The country offers a top destination for companies looking for manufacturing partners with high-quality, cost-effective, efficient processes for silicone injection molding projects. Why do...

A Brief Guide to Compression Molding Technology

Compression molding uses a thermosetting process to shape materials such as rubber, composites, or resins. It’s a versatile manufacturing technique useful in rapid prototyping and low-volume manufacturing projects. This post examines the technology, its benefits, and...

Industries That Rely on Plastic Injection Molding

Plastic components feature excellent flexibility in production processes, making them a popular choice in many industries. Manufacturers can create components that meet clients' exact requirements and specifications, benefiting many industries. However, choosing a...

Understanding the Three Main Types of Sheet Metal Fabrication: Forming, Cutting, & Joining

There are three methods of sheet metal fabrication, each with several sub-methods. This post walks you through each method in detail. 1 Cutting Techniques for Sheet Metal Fabrication Cutting is the primary phase of sheet metal fabrication. There are two types of...

12 CNC Milling Advantages

CNC milling is a popular rapid prototyping and mass manufacturing process used by companies and machine shops worldwide. This highly efficient and effective production method has several applications, making it a go-to choice for component manufacturing in a wide...

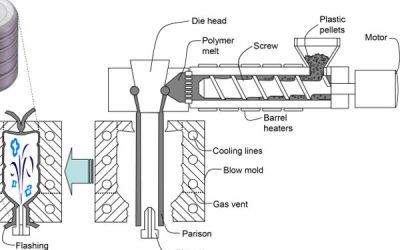

An Overview of the Blow Molding Process

The process of blow molding involves the formation of plastic products using thermoplastics. These products have a hollow design and are formed through the heating and inflation of plastic tubes known as "preforms" or "parison." The manufacturer places preforms...

Crafting Elegance: Exploring the Art of Resin Jewelry Molds

The world of jewelry design has witnessed a revolution in recent years, driven by the infusion of innovative materials and techniques. Resin jewelry molds have emerged as a prominent player in this transformation, offering designers the freedom to create unique,...

Small Batch, Big Impact: The Rise of Low-Volume Manufacturing

In recent years, a paradigm shift has been observed in the manufacturing industry, with a growing emphasis on small-batch production. This departure from traditional mass production methods signifies the rise of low-volume manufacturing, a trend driven by diverse...

Harnessing Precision and Durability: The Transformative Role of Liquid Silicone in Mold Making

In the realm of mold making, innovation has always been a driving force, shaping the efficiency and quality of manufacturing processes. Liquid silicone for molds has emerged as a game-changer, offering a versatile and dependable material that addresses the demands of...

Unlocking the Potential of Die Casting: From Complex Shapes to High Volumes

Die casting has revolutionized manufacturing, providing a pathway to craft intricate shapes and meet high-volume production demands seamlessly. In this article, we delve into the manifold benefits and applications of die casting, unlocking its potential for diverse...

Liquid Silicone Injection Molding: Revolutionizing Precision and Versatility in Manufacturing

In the dynamic world of manufacturing, processes and materials are constantly evolving through innovation. One of these revolutionary developments is liquid silicone injection molding, a cutting-edge manufacturing process that has gained popularity for its precision,...

Prototype and Manufacturing Services Near By

Rapid Prototyping Services

Turn your ideas into reality fast with our rapid prototyping services. From concept to 3D printing, we bring your vision to life quickly and accurately. Stay ahead of the curve and accelerate your product development process with us.

Silicone Molding

Experience seamless production with our silicone molding expertise. Our precise techniques ensure high-quality, custom molds that bring your designs to life with exceptional detail and durability. Whether you’re crafting prototypes or mass-producing products, our silicone molding services offer efficiency and reliability, empowering you to achieve your goals with confidence.