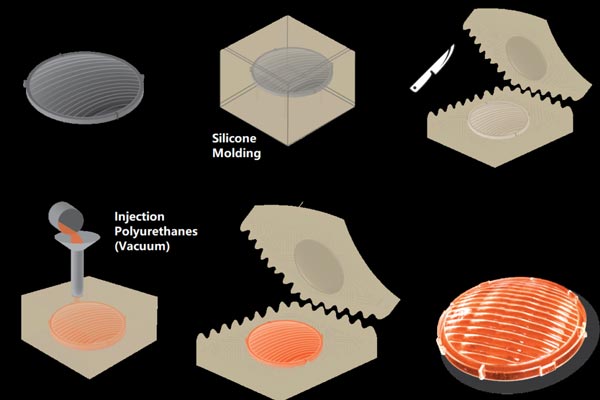

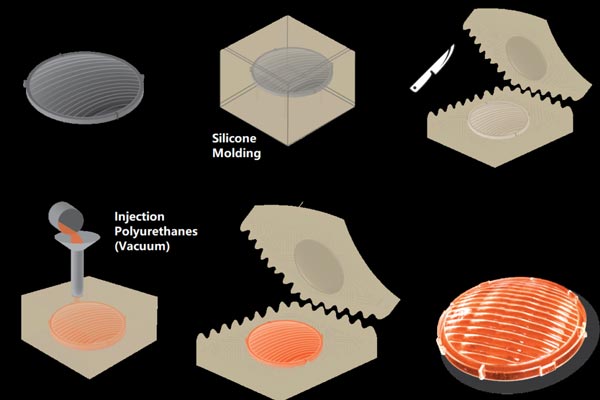

by Nice Rapid | Apr 21, 2020 | Vacuum Casting

Vacuum casting has revolutionized the way industrial parts and prototypes are created; the casting process provides producers with a fast and effective way of producing high-quality parts/products and samples in small quantities. The vacuum casting process utilizes...

by Nice Rapid | Apr 20, 2020 | Liquid Silicone Rubber Molding

The liquid silicone rubber molding has been in the market for more than 20 years. However, it is only that it has given the right attention. It has been used in different industries and is creating new opportunities. At present, around 25 to 30% of the silicone market...

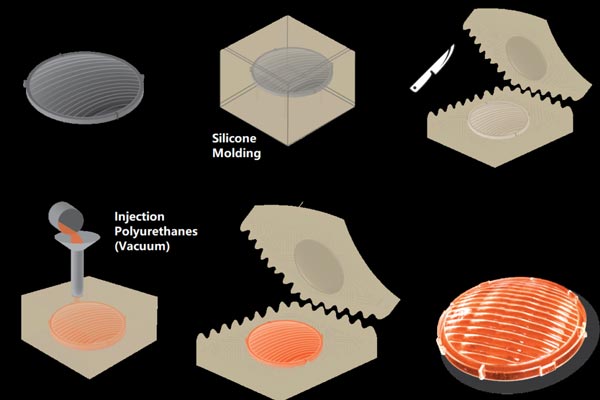

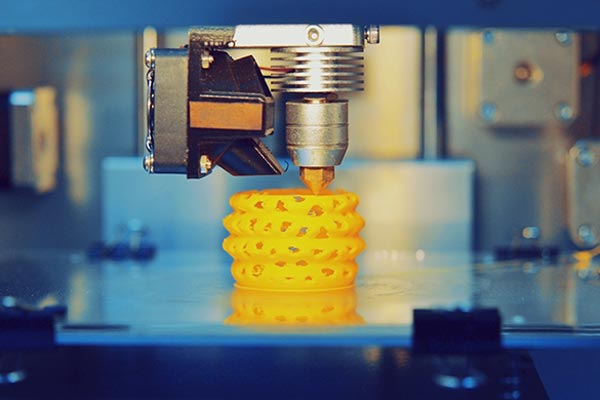

by Nice Rapid | Apr 15, 2020 | 3D Printing

3D printing is amongst the most cutting-edge technology that allows the creation of a physical part/product from a wide range of digital models depending on your printing needs and requirements. In the beginning, the first printing service was introduced in the 1980s...

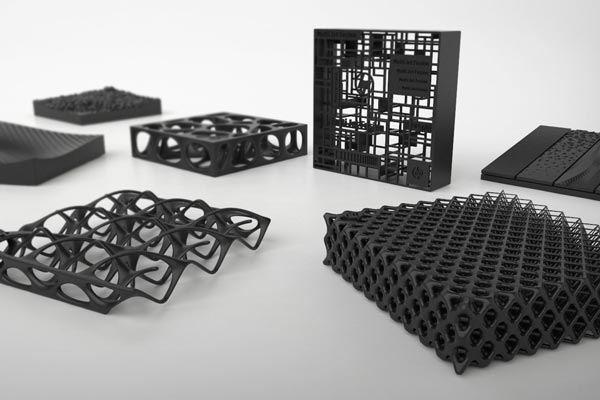

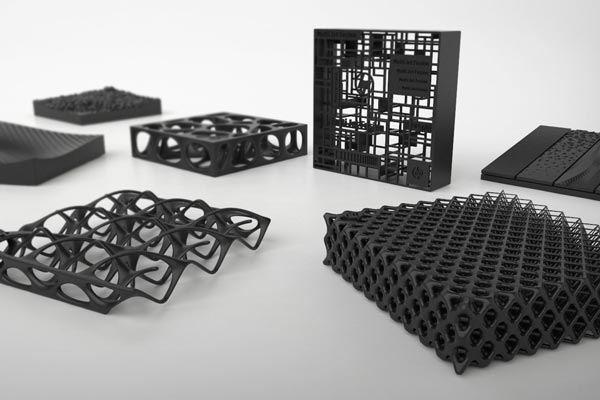

by Nice Rapid | Apr 14, 2020 | 3D Printing

3D printing refers to coming up with three-dimensional items from a digital page or picture. This type of printing enables an artist to produce more complex artifacts and make them more visual. Among the essential tools for 3D printing include 3D printers and software...

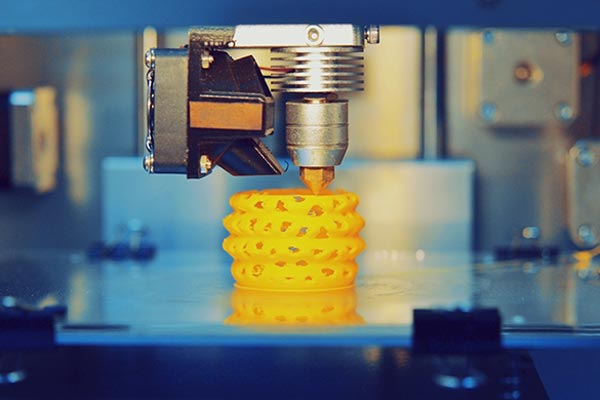

by Nice Rapid | Mar 30, 2020 | Liquid Silicone Rubber Molding

Curious about what liquid silicone rubber molding is all about? You have come to the right page. We are going to talk about this manufacturing process that involves liquid silicone rubber to create pliable and durable parts in large volumes. This silicone rubber...