CNC Machining uses computer-controlled machine tools to create precise components from various materials. This manufacturing process offers exceptional accuracy, repeatability, and surface finish quality. You can achieve tolerances measured in thousandths of an inch consistently.

Computer numerical control eliminates human error from machining operations by automating every action. Programmed instructions control every aspect of the cutting process with unwavering precision. Tool paths, speeds, and feeds remain perfectly consistent across all parts in a production run, ensuring that the first part is identical to the thousandth. This digital replication is the cornerstone of modern mass production and custom manufacturing.

Modern CNC machines incorporate advanced features like automatic tool changers for uninterrupted operation, probing systems for automated setup and in-process verification, and adaptive control that adjusts cutting parameters in real-time based on tool load. These capabilities enhance precision while reducing setup times and operator intervention requirements, leading to higher efficiency and lower costs per part.

What Programming Techniques Optimize CNC Machining Performance?

Programming represents the foundation of successful CNC machining operations. G-code instructions control machine movements, spindle speeds, and feed rates with mathematical precision. Proper programming balances productivity with tool life and part quality.

Computer-aided manufacturing software generates optimized tool paths automatically. These programs consider material properties, cutting tool capabilities, and machine limitations. Advanced software includes simulation capabilities that prevent costly programming errors.

Consider these programming best practices:

- Optimize tool paths for minimal air cutting time

- Use appropriate speeds and feeds for each material

- Include adequate safety margins and clearance moves

- Implement tool life monitoring and replacement strategies

- Program inspection routines for quality verification

Experienced programmers understand the relationship between cutting parameters and results. They adjust programs based on real-world performance and optimization opportunities.

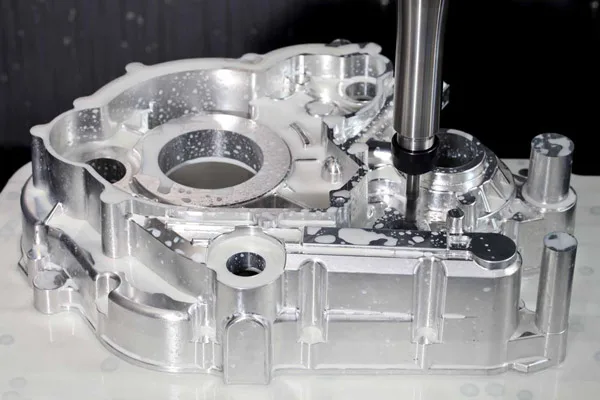

CNC auto parts

How Do You Select Tools and Work holding for Maximum Results?

Tool selection is a critical decision that significantly impacts CNC machining performance, component quality, and overall project economics. Cutting tool geometry, substrate material, coating technology, and the programmed tool paths affect machining outcomes directly. A perfect match between the tool and the specific material removal operation is essential for optimal results.

Carbide tools provide excellent performance for most machining applications due to their superior hardness and wear resistance at high temperatures. For specialized applications, ceramic and CBN (Cubic Boron Nitride) tools handle hardened steels and high-speed operations, while Polycrystalline Diamond (PCD) tools are ideal for machining highly abrasive non-ferrous materials. Advanced tool coatings, such as TiAlN (Titanium Aluminum Nitride) or AlCrN (Aluminum Chromium Nitride), extend tool life, allow for higher speeds, and improve surface finishes significantly by reducing friction and heat.

Workholding systems are responsible for securing components immovably during machining while providing maximum tool access. Fixture design is a science that affects both machining accuracy and cycle times directly. Proper workholding prevents vibration, chatter, and part movement, which are primary causes of poor surface finish and lost dimensional accuracy throughout cutting operations.

Modular fixturing systems, such as tombstones and grid plates, provide exceptional flexibility for accommodating different part geometries with minimal investment. Quick-change vise jaws and pallet systems dramatically reduce setup times between different jobs, increasing machine utilization. Investing in high-quality, dedicated workholding is not an expense but a critical investment to maximize machine productivity and guarantee part accuracy.

What Quality Control Measures Ensure Machining Success?

A comprehensive quality control protocol is integral to the machining process, not just a final inspection. Dimensional inspection verifies that machined parts meet all specification requirements on the print. Coordinate measuring machines (CMMs) provide precise, non-contact measurements for complex geometries and free-form surfaces. In-process measurement capabilities, often using machine-integrated probes, enable real-time adjustments for tool offsets during machining operations, catching errors immediately.

Surface finish measurement quantifies machining quality objectively using profilometers. Roughness average (Ra) measurements ensure parts meet both functional requirements, like sealing or reduced friction, and appearance requirements. A consistent surface finish across a batch is a key indicator of a stable machining process and proper tool condition, signaling that no unexpected wear or vibration has occurred.

First article inspection (FAI) thoroughly validates programs and setups before full production begins, often against a detailed AS9102 or PPAP checklist. Statistical process control (SPC) actively monitors key dimensions throughout production runs using data collected from periodic checks. Control charts visually identify trends that indicate natural tool wear or process drift, allowing for proactive intervention before parts fall out of tolerance.

Achieve Manufacturing Excellence with Professional CNC Machining Services

CNC machining delivers exceptional precision, reliability, and versatility for the most demanding applications. You achieve optimal results through a synergistic focus on proper programming, strategic tool selection, and rigorous quality control measures. The key is to focus on understanding your specific technical and performance requirements and leveraging advanced machining capabilities to meet them.

Expert machining partners provide more than just machine time; they offer specialized equipment, deep programming expertise, and rigorous quality assurance systems necessary for complex projects. They provide invaluable Design for Manufacturability (DFM) feedback, helping you optimize designs for easier, faster, and more cost-effective production while achieving consistent, high-quality results.

Nice Rapid offers comprehensive CNC machining services with advanced equipment and experienced programming teams. Our precision machining capabilities serve diverse industries with exacting requirements. Contact us today to discuss your CNC machining needs and experience manufacturing excellence.