In the early days of manufacturing, products were made one by one. However, times changed when the demand for faster and cheaper products entered the picture. It has led to the factories we have today and, of course, mass production. Nowadays, these factories can churn out millions of products in a year.

How about the demand for products in less quantity like a thousands, hundreds, or even ten per year. The answer is low volume manufacturing. It has been a practice for the medical industry, for instance, to make products in small quantities for clinical trials and market tests before it will be mass-produced.

In this article, we will be taking a closer look at the top four benefits of low-volume production and how it relates to the future industry.

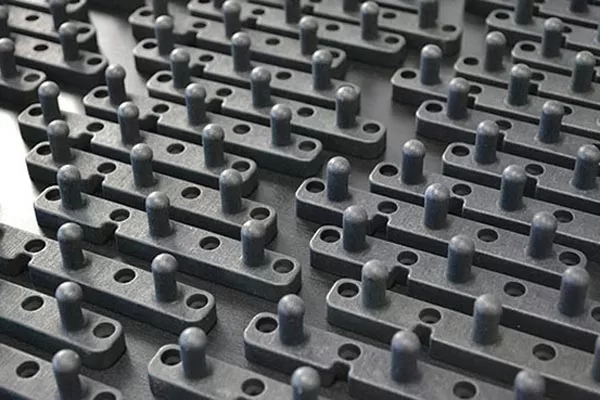

Low volume manufacturing parts

Understanding Low-Volume Manufacturing

Low-volume manufacturing is like a bridge that connects prototyping and mass production to make sure that the transition between one and the other is as smooth as possible. One of the requirements in the implementation of this manufacturing type is to have technologies with high efficiency and repeatability. It is a complex endeavor where design, verification, and continuous improvement are involved in the product to be a success.

Customization and Low-Volume Production

The trend in the modern industry is moving away from masse production and more into manufacturing parts in small batches. Thanks to the changing customer expectations on product quality and customization, there is a growing demand for low volume production. And since more customers are ready to buy more often, there is also a need for product launch to be shortened. The amount of time for the idea of a full-fledged product has become more vital than ever.

Thanks to low-volume manufacturing, companies can manufacture parts from 100 to 100,000 pieces. It is also necessary for companies to have small production runs to test their products with the market before they go into full volume production. This strategy can increase decision efficiency and will save the investors some money in case the idea does not work as expected.

Benefits of Low-Volume Production

Everyone can benefit from manufacturing small batches. Here are some of the advantages of using low-volume production.

- It can make redesigning easier. When the manufacturability of design has been established, there will still be room for improvement. It can be done when you make a small pilot batch and test it in real conditions. Based on the feedback, improvements can be made before going into full production.

- It has a lower cost. Using low-volume manufacturing techniques takes less time and money than doing mass production with all the equipment and tooling.

- It serves as a bridge between prototyping and full-pledged production. Prototyping is not the end product, but it helps the product developers to see faults and have them fixed manually. That is where low volume production comes in. It serves as a link between prototype and industrial production. In making the pilot batch, the technology and product positioning is already established. This batch will be market-tested, and a final review of the design will be done before bringing it to the market.

- Shortens the time to market. The market is highly competitive, and the first launch a new product emerges as the winner. Low-volume manufacturing enables developers to produce their ideas in the shortest time possible while they prepare for mass production. This allows them to get ahead of their competition.