Every year, more than 30,000 new products launch into the market. With so many additions, how can your product stand out from the competition? Prototyping offers manufacturers a useful tool in the product development stage, giving them a replica of the finished design for assessment and testing.

Prototyping is the creation of a nonfunctional or functional sample to validate concepts, test designs, and receive project approval from management or the board. Prototyping allows designers to put their products to the test and learn from their successes and mistakes.

Gaining insight from the prototyping phase lets designers, brands, and manufacturers get on the same page with the project requirements and goals. Expert engineers can use several methods to bring your prototype to life.

Many innovative manufacturing techniques allow engineers and designers to turn any project into reality. Some of the more commonly used prototyping tools include the following.

- Injection molding

- Selective laser melting

- Multi-jet fusion (MJF)

- Stereolithography (SLA)

- Urethane casting

- CNC machining

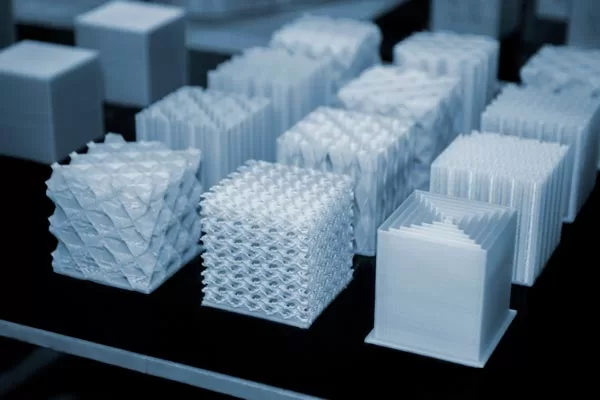

SLA parts

What are the Advantages of Rapid Prototyping?

Rapid prototyping offers brands and designers several advantages for their projects. Let’s unpack the core reasons to consider prototyping in product development best practices.

Production Speed

Prototyping allows designers and manufacturers to assume the best manufacturing method for optimal product output volumes. Brands benefit from a faster time to market and better product availability, with short restocking times.

Reduce Development Costs

Rapid prototyping allows brands and designers to produce a test product fast. It will enable designers to work through changes without going through the costly expense of making the changes after production starts.

Functionality Testing

The prototype is a to-scale sample of the finished product. You can expect all features and operations to exist in the prototype for testing purposes. Testing allows designers to fine-tune their concepts and turn them into top-selling products.

Does the prototype offer a solid user experience? Does the prototype achieve the project goals? By testing and assessing the prototype, designers can make the necessary changes for product improvement.

Eliminate Product Failure Risk

Prototyping allows designers to identify compliance and safety issues before the product goes into mass manufacturing.

Prototyping clears up any risk factors that might cause a failure risk when the prototype goes to the mass manufacturing stage.

There are several materials available for the prototyping process, and designers can mock up real examples of products in a range of materials to suit the brand’s needs.

Test a Full Range of Designs

Rapid prototyping allows engineers to test designs that might be otherwise too expensive to produce. Components with sharp corners, thin walls, and designs inaccessible to CNC machines are made through layering manufacturing techniques, such as 3D printing.

Also known as “additive” manufacturing, 3D printing is one of the more popular prototyping tools used in manufacturing and design projects.

Creating design prototypes with varying component geometries assists designers with understanding the trade-off between aesthetics and function in prototype testing.

Once testing various prototypes, designers, and engineers can minimalize their designs down to simple formats that still maintain the function of the prototype components.

Part Consolidation

Rapid prototyping allows designers and engineers to test single components that, when produced for end-use, require production as multiple parts.

Consolidating several fabricated or machined components in the rapid prototyping process is cost-effective and allows designers and engineers to explore additional functions.

Test Materials

Rapid prototyping allows engineers and designers to choose from a range of materials to suit their needs.

In Closing

Rapid prototyping is necessary for the product development process. From wasting money, time, and reputation on future upgrades to allowing a viable working prototype for designers to test, rapid prototyping offers brands, manufacturers, and designers a valuable resource in product planning and design.