In today’s modern life, 3D printing is a popular process in creating objects using a digital model. 3D printers are referred to as additive manufacturing because it is done by adding a very thin layer to the purpose one at a time.

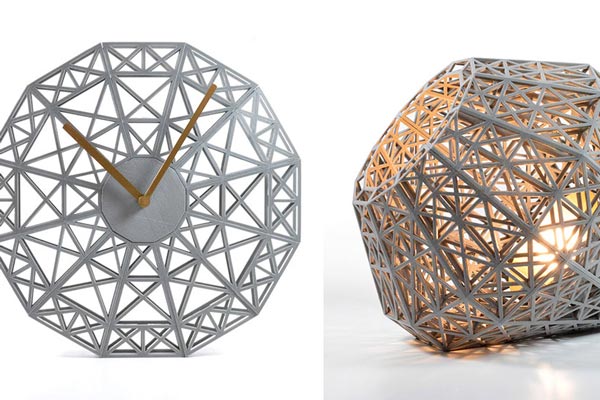

Lamp clock paris 3d printing

Understanding Additive Manufacturing

The resemblance to printing is not perfect. The computer printers run a row at a time. If you know what plotters are, 3D printers work similarly to this. It moves a print head on the X and Y axis to make a pattern. With 3D printers, you will be using plastic to draw the printer and not ink. The 3D printer draws a model, then the printer’s head will move up, then another pattern is created on top of the first pattern.

How Does 3D Printer Works?

The most popular type of 3D printers is the SLA (stereolithography) and the FDM (fused deposition modeling): Let’s differentiate one from the other by discussing how each type of 3D printer works.

FDM

In FDM, its source material is a roll of filament. The strands usually measure 1.75 or 2.85 millimeters thick, and rolled in the spindle. The printer will heat the filament, squeezes it out into an extruder nozzle, and place layers of it on a surface. The layers are quite thin, and as each molten layer is placed on top of the first layer, it fuses together as it cools down.

SLA

The source material used in SLA is liquid resin. As a start, the build tray is lowered in the resin in an upside-down position, and the light generates a chemical reaction in the resin, which hardens it. The layers are exposed to light. Then the printer will slightly raise the platform out of the resin pool, which exposes the succeeding layer to light.

In fused-deposition modeling is the usual form of material extrusion 3D printing, while the SLA is the popular form of light polymerization 3D printing. For hobbyists, entrepreneurs, consumers, small businesses, and educators who are looking for an affordable 3D printer, the SLA and FDM printing methods are quite helpful. However, they are only limited to the production of nylon-like, plastic composites, and plastic materials.

Other Forms of 3D Printers

There are other forms of 3D printers that you can choose from, but it means you need to invest in it as most of them cost very high—the power bed 3D printer wherein it uses powder when printing is also a good option.

The laminated object manufacturing that uses glue sheets material can also be considered. Another printing method is the directed energy deposition, which is the result if the welding machine and FDM is combined. The electron beam freeform process wherein an electron beam is sent in a vacuum to generate molten metal based on a 3D model.

The other forms of 3D printing are used to manufacture metal parts, while the SLA and FDM are used to produce plastic components. These methods have one thing in common. They are all creating new objects by adding and fusing together a raw material.