NICE Rapid Blog

Latest news and knowledge to share.

Beyond Prototyping: Material and Process Breakthroughs in Vacuum Casting

What is Vacuum Casting? It's a process used to create small batches (10-50+ parts) of high-quality polyurethane parts from a silicone mold. A master pattern (typically 3D printed and finished to perfection) is used to create a silicone mold. Under vacuum (to remove...

Why Choose Vacuum Casting for Medical Device Development?

In the precise and highly regulated realm of medical technology, the choice of appropriate prototyping and low-volume manufacturing techniques is a crucial strategic choice. While 3D printing is widely used, vacuum casting stands out as the solution of choice for...

Maximizing Flexibility and Customization for Specialized Markets with Low Volume Manufacturing

Low Volume Manufacturing offers significant advantages for specialized applications and emerging markets. You get flexibility, reduced inventory requirements, and faster market response times. This approach enables product testing without substantial capital...

Understanding Material Properties and Industrial Applications in Silicone Molding

Silicone molding creates flexible, durable parts that withstand extreme conditions. Silicone materials offer exceptional temperature resistance from -65°F to 400°F. You get excellent chemical compatibility and biocompatibility for medical applications. Silicone...

What Makes Blow Molding Perfect for Your Container Applications?

Blow molding creates hollow plastic containers through air pressure expansion. This process works perfectly for bottles, tanks, and complex hollow shapes. You get excellent material distribution and strong, lightweight containers at competitive costs. The process...

Liquid Silicone Rubber Molding as an Advanced Processing Method for High-Precision Components

Liquid silicone rubber molding uses two-part liquid systems that cure rapidly under heat. This advanced process produces high-precision components with exceptional material properties. You get superior dimensional accuracy and surface finish compared to conventional...

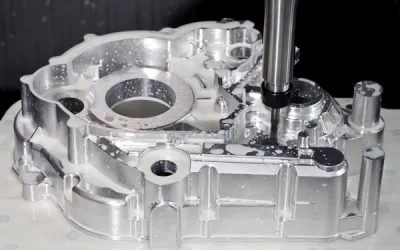

How Does CNC Machining Deliver Unmatched Precision for Your Parts?

CNC Machining uses computer-controlled machine tools to create precise components from various materials. This manufacturing process offers exceptional accuracy, repeatability, and surface finish quality. You can achieve tolerances measured in thousandths of an inch...

CNC Machining vs. Additive Manufacturing: When to Choose Which for Robotics

Robotics manufacturing demands precision, durability, and efficiency that can make or break a project's success. Both CNC machining and additive manufacturing offer distinct advantages for creating robotic components, but selecting the wrong method can lead to costly...

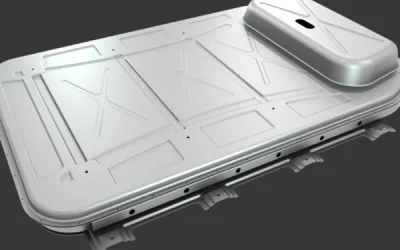

Aluminum Extrusion for Modular EV Battery Frames: Lightweight & Scalable

The electric vehicle industry faces mounting pressure to reduce weight while maintaining safety and performance standards in battery pack designs. Traditional manufacturing approaches often fall short when automakers need flexible solutions that can adapt across...

Laser-Cut Sheet Metal Facades: Revolutionary Design Solutions for Modern Architecture

Laser-cut sheet metal facades represent a revolutionary approach to modern architecture, transforming the way buildings balance visual appeal with essential structural requirements. These precision-engineered panels combine advanced cutting technology with traditional...

How High-Pressure Die Casting is Enabling Mass Production of EV Components

Electric vehicle production has reached a critical turning point where traditional manufacturing methods can no longer keep pace with growing demand. Pressure die casting has emerged as the dominant solution for mass-producing lightweight, complex EV components while...

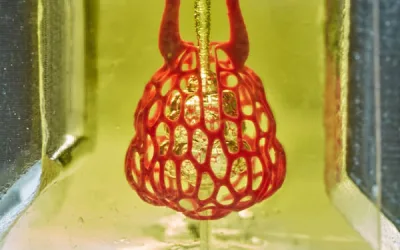

3D Bioprinting Vascular Networks: Advancing the Future of Organ Transplant Research

You are entering a field where engineering and biology meet to solve one of medicine’s toughest challenges—creating functional blood vessel networks for lab-grown organs. Without these networks, even the most advanced 3D-printed tissues cannot survive once implanted....

Prototype and Manufacturing Services Near By

Rapid Prototyping Services

Turn your ideas into reality fast with our rapid prototyping services. From concept to 3D printing, we bring your vision to life quickly and accurately. Stay ahead of the curve and accelerate your product development process with us.

Silicone Molding

Experience seamless production with our silicone molding expertise. Our precise techniques ensure high-quality, custom molds that bring your designs to life with exceptional detail and durability. Whether you’re crafting prototypes or mass-producing products, our silicone molding services offer efficiency and reliability, empowering you to achieve your goals with confidence.