by Nice Rapid | Dec 26, 2022

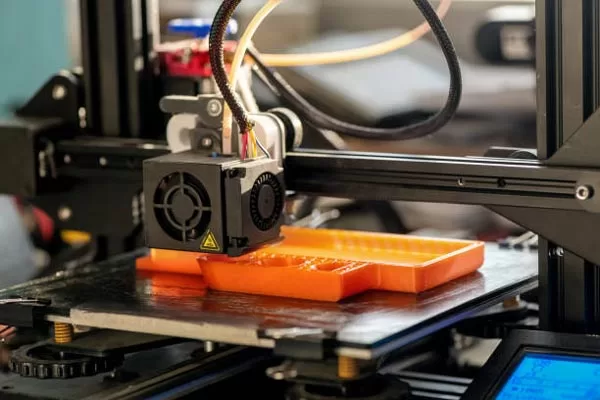

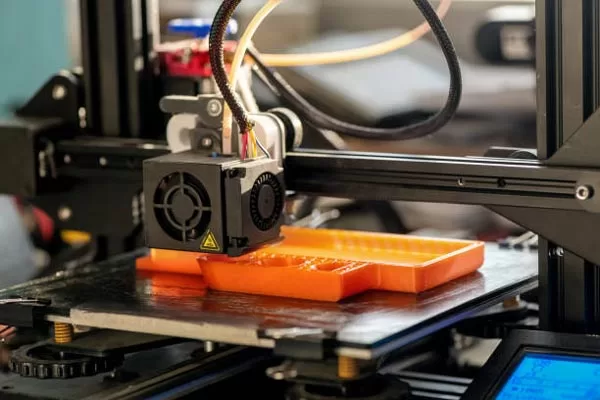

The Six Biggest Innovations that Impacts Additive Manufacturing Additive manufacturing and 3D printers have changed the way we make things. It’s less expensive, more efficient, and is becoming standard. There are a lot of benefits to this new manufacturing...

by Nice Rapid | Nov 30, 2022

Tips for Rapid Prototyping Success Rapid prototyping has been around for a while, but it’s taken off in the last few years. Today, people are using rapid prototyping for everything from creating the latest ideas for new inventions to creating new products for...

by Nice Rapid | Nov 3, 2022

Three Main Benefits of Using LSR Molding Liquid silicone rubber (LSR) molding is a popular manufacturing process that offers many benefits over traditional injection molding. LSR is a two-part process that uses a platinum-cured silicone mold and a Reaction Injection...

by Nice Rapid | Apr 29, 2022

8 Important Reasons Why You Need Prototypes There are several steps in building a product before pushing it for mass production. In each stage, the main goal is to have a product for specific target customers and solve their pain points. To evaluate if this product...

by Nice Rapid | Apr 24, 2022

The Impact of Aluminum Extrusion Process on the Environment The industrial revolution might have been ages ago, but we can still feel its impact on the environment. We have pushed the limits, and there is obvious stress on the basic life support systems. Its...