Navigating the Nuances: A Comprehensive Guide to Low-Volume Production

In the world of manufacturing, mass production has long been the dominant model, driving down costs for consumer goods through economies of scale. However, a powerful shift is underway. The rise of niche markets, rapid technological innovation, and the demand for customization have propelled Low-Volume Production into the spotlight.

Low-volume production, often defined as manufacturing batches from a few dozen to a few thousand units, is a strategic approach used for prototyping, market testing, limited editions, and specialized products. While it forgoes the per-unit cost advantages of mass production, it offers unparalleled flexibility and speed to market.

Success in low-volume manufacturing isn’t automatic; it requires careful consideration of a unique set of factors. Missteps can quickly erode profitability and nullify its core benefits. This article provides a comprehensive guide to the critical factors you must consider when embarking on a low-volume manufacturing journey.

1. Defining Your “Why”: The Core Objectives

Before any technical decisions are made, you must have absolute clarity on your goals. The purpose of your production run will dictate nearly every subsequent choice.

- Prototyping & Design Validation: Is the goal to create functional prototypes for testing? The focus here is on speed, material properties, and the ability to iterate quickly. Fidelity to the final design is key, but surface finish might be secondary.

- Market Testing & Launch: Are you producing a limited batch to gauge customer interest? The units must represent the final product in look, feel, and function to gather accurate feedback. Cost-per-unit is more critical here than in pure prototyping.

- Bridge Production: Are you using low-volume to fulfill initial orders while your mass-production tooling is being developed? The process must be scalable and the parts must be identical to what will later be mass-produced.

- Specialized & High-Value Products: Are you making aerospace components, medical devices, or luxury goods? The emphasis is on extreme quality, material certification, and traceability, with cost being a less dominant factor.

2. The Manufacturing Process: Choosing the Right Tool for the Job

The selection of a manufacturing process is the most consequential decision in low-volume production. Each technology offers a different balance of cost, speed, quality, and material options.

A. Additive Manufacturing (3D Printing)

Best For: Extreme complexity, rapid iteration, and single-piece integration.

Processes: FDM (plastic prototypes), SLA/DLP (high-detail resin parts), SLS (durable nylon parts), Metal SLM/DMLS (functional metal components).

Pros: No tooling costs, unparalleled design freedom, very fast for small batches.

Cons: Can be expensive per part at higher volumes, surface finish may require post-processing, anisotropic material properties.

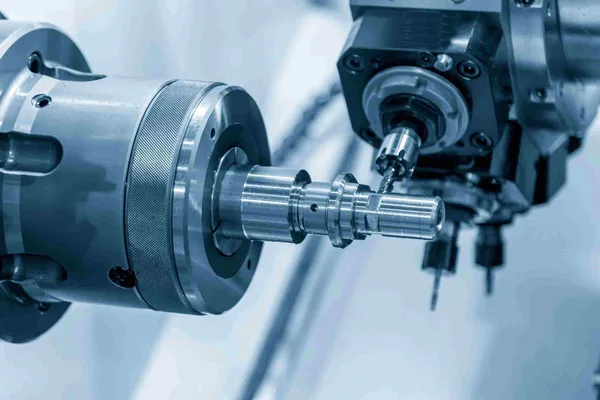

B. CNC Machining (Subtractive Manufacturing)

Best For: High-precision, functional parts from a wide range of engineering-grade materials (metals, plastics, composites).

Pros: Excellent strength and surface finish, wide material selection, no tooling required.

Cons: Higher cost per part than injection molding at scale, material waste (subtractive), geometric limitations compared to 3D printing.

C. Vacuum Casting (Urethane Casting)

Best For: Creating 10-100 copies of a master pattern in polyurethane resins that mimic final production plastics.

Pros: Lower cost than CNC for small batches, good surface finish and detail, can produce parts in flexible or rigid materials.

Cons: Requires a master pattern (often 3D printed or CNC machined), mold life is limited (~20-50 parts), not suitable for high-temperature or harsh chemical environments.

D. Rapid Tooling for Injection Molding

Best For: Producing hundreds to low-thousands of parts in final production thermoplastics.

Pros: Parts are identical to mass-produced items, low per-part cost after tooling is made.

Cons: High upfront cost and lead time for the mold (though lower than production tooling), design changes are difficult and expensive once the mold is made.

CNC machine

Vacuum casting product

3.Cost Structure and Budgeting: Beyond the Unit Price

The financial dynamics of low-volume production are fundamentally different. A holistic view of cost is essential.

- Upfront (NRE) Costs: This includes design for manufacturability (DFM) analysis, programming (for CNC), and most significantly, tooling. For processes like injection molding, tooling can be 60-80% of the initial project cost.

- Per-Unit Cost: This is the cost to produce each individual part, including material, machine time, and labor.

- The Breakeven Analysis: A crucial exercise is to calculate the volume at which the high NRE of a process like injection molding is offset by its low per-unit cost, making it cheaper than a no-tooling process like CNC machining. Plotting this will visually reveal the most cost-effective process for your target volume.

3d printed parts

4. Design for Manufacturability (DFM)

DFM is the practice of designing your product to optimize it for the chosen manufacturing process. It is non-negotiable for controlling costs and ensuring quality.

- For CNC Machining: Minimize deep pockets (hard-to-reach areas), specify appropriate tolerances (tighter = more expensive), and consider how the part will be fixtured.

- For Injection Molding: Design uniform wall thicknesses, incorporate drafts (taper) for easy ejection, and avoid undercuts that complicate the mold.

- For 3D Printing: Orient the part to minimize support structures, consider anisotropic strength, and leverage the ability to create complex internal geometries.

Engaging with your manufacturing partner early for a DFM analysis can prevent costly redesigns and production headaches.

5. Supply Chain and Partner Selection

Your choice of manufacturing partner can make or break your low-volume project.

- Specialization: Seek out suppliers who explicitly specialize in and are equipped for low-volume, high-mix work. A factory built for millions of units may not be a good fit for a 500-unit order.

- Communication & Transparency: Choose a partner who communicates clearly about capabilities, lead times, and costs. They should be a collaborative resource, not just an order-taker.

- Quality Control: Inquire about their Quality Management System (QMS). For low volume, first-article inspection (FAI) and detailed documentation are often more critical than statistical process control.

Plastic parts

6. Lead Time and Time-to-Market

Speed is often a primary driver for choosing low-volume production.

- Prototype to Part Timeline: Additive manufacturing offers the fastest turnaround, sometimes in days. CNC machining follows closely. Processes involving tooling, like injection molding, will have longer lead times due to mold fabrication.

- Scalability Planning: If your low-volume run is successful, how quickly can you scale? Have a plan for transitioning to a higher-volume process to avoid stock-outs.

7. Quality Control and Certification

With fewer units, each one carries more value. Robust QC is paramount.

- Inspection Techniques: Depending on the criticality, this can range from simple caliper checks to full CMM (Coordinate Measuring Machine) inspection and 3D scanning to verify against the CAD model.

- Material Certification: For regulated industries (medical, aerospace), you may require mill certificates for raw materials, proving their composition and properties.

- Traceability: Each part may need to be traceable back to its material batch, machine, and operator. Ensure your partner can provide this.

3D printing post processing

8. Post-Processing and Finishing

Parts rarely come off the machine ready for the end-user. Factor in the requirements and costs for secondary operations.

- Support Removal: (3D Printing)

- Sanding, Polishing, Bead Blasting: To improve surface finish.

- Painting, Plating, Anodizing: For aesthetics, corrosion resistance, or hardness.

- Assembly: If your product consists of multiple components, the cost and time for assembly must be included.

Conclusion: A Strategic Balancing Act

Low-volume production is a powerful strategy for innovation, agility, and serving niche markets. Success hinges on viewing it not as a “smaller” version of mass production, but as a discipline with its own unique rules.

By carefully weighing your objectives, selecting the optimal manufacturing process, understanding the true cost structure, and partnering with the right supplier, you can leverage low-volume production to de-risk your product launch, respond dynamically to the market, and bring high-quality, specialized products to life efficiently and effectively. It is a balancing act, but one that offers a significant competitive advantage in today’s fast-paced world.

Summary Table: Key Factors at a Glance

|

Factor |

Key Considerations for Low Volume Production |

| Cost | High unit cost; focus on Total Cost of Ownership (TCO), not just per-part price. Amortize tooling over small batches. |

| Design (DFM/DFA) | Simplify, use standard parts, design for the specific process (CNC, 3D print), and avoid unnecessarily tight tolerances. |

| Process Selection | Match the technology to the volume: 3D Printing (1-100), CNC Machining (1-10,000), Rapid Tooling (100-5,000). |

| Materials | Ensure availability in small quantities, consider cost, and verify compatibility with the chosen process. |

| Supply Chain | Partner with agile, LVP-friendly suppliers. Manage lead times and adopt lean inventory practices. |

| Quality Control | Implement rigorous First Article Inspection (FAI) and in-process checks. Meticulous documentation is vital. |

| Scalability | Plan for the future. Consider how the design and manufacturing process can evolve if demand increases. |

| Post-Processing | Often manual and labor-intensive. Plan for significant time and cost. Critical for aesthetics, function, and durability. |