Comprehensive Guide to Aluminum Extrusion Finishes: Enhancing Performance and Aesthetics

Introduction to Aluminum Extrusion Finishing

Aluminum extrusion has become a cornerstone of modern manufacturing due to its exceptional versatility, strength-to-weight ratio, and sustainability. While the extrusion process itself creates the basic profile shape, the finishing process is what truly unlocks aluminum’s full potential. Finishes not only protect the metal but can transform its appearance and functionality to meet specific application requirements. This guide provides an in-depth exploration of aluminum finishing options, detailing their processes, benefits, and ideal applications to help you make informed decisions for your projects.

Aluminum extrusions alloy

Anodized aluminum parts

Brushed metal finishing

Why Finishing Matters: Beyond Basic Protection

Advanced Corrosion Protection

While aluminum naturally forms a protective oxide layer (Al₂O₃), this passive film is only 2-4 nanometers thick. Finishing processes enhance this protection through:

- Anodizing: Creates an oxide layer up to 25 microns thick

- Conversion coatings: Provide additional chemical resistance

- Barrier coatings: Completely isolate the metal from its environment

Different environments demand different levels of protection:

- Mild (indoor): Mechanical finishes may suffice

- Moderate (urban outdoor): Powder coating recommended

- Severe (marine/industrial): Hardcoat anodizing required

Surface Engineering for Functional Performance

Modern finishes can impart specialized properties:

- Electrical insulation (anodizing)

- Thermal management (special ceramic coatings)

- Wear resistance (hardcoat anodizing)

- Chemical resistance (PTFE-based coatings)

- Light reflectivity (high-gloss mechanical finishes)

Aesthetic Customization Options

Today’s finishing technologies offer unprecedented design flexibility:

- Color matching to Pantone standards

- Special effects: Hammer tone, metallic flecks, wrinkle textures

- Dimensional appearance: Brushed, bead blasted, or mirror finishes

- Branding integration: Direct printing and laser marking

Detailed Finishing Process Breakdown

1. Mechanical Finishing Systems

These physical processes prepare surfaces and create visual effects:

A. Abrasive Finishing

- Belt grinding: For heavy stock removal (80-120 grit)

- Orbital sanding: Creates uniform scratch patterns (180-320 grit)

- Micro-abrasive blasting: Uses glass beads or aluminum oxide (50-100μm)

B. Polishing Processes

- Cut-down polishing: Removes extrusion lines with progressively finer compounds

- Color buffing: Creates high reflectivity (Ra < 0.1μm)

- Barrel finishing: Mass finishing for small parts using ceramic media

C. Specialty Textures

- EDM texturing: Creates precise micro-patterns

- Laser ablation: For custom surface designs

- Embossing: Roller-based pattern transfer

Industry Applications:

- Aerospace: Mirror finishes for reduced air resistance

- Medical: Ultra-smooth surfaces for cleanability

- Architecture: Custom texture matching

2. Chemical Pretreatment Processes

Critical for coating adhesion and performance:

|

Step |

Process |

Parameters |

Purpose |

| Degreasing | Alkaline cleaner | 50-70°C, pH 11-13 | Remove oils |

| Etching | NaOH solution | 60°C, 5-10% conc | Create micro-roughness |

| Desmutting | HNO₃ solution | Ambient, 15-30% | Remove smu |

| Conversion | Chromate/TCCT | 30-50°C, 2-5 min | Enhance corrosion resistance |

Emerging Technologies:

- Nanoceramic pretreatments

- Zirconium-based systems (chrome-free)

- Plasma pretreatment for difficult substrates

3. Anodizing Technology Deep Dive

Type II (Decorative) Anodizing

- Electrolyte: 15-20% H₂SO₄

- Voltage: 12-18V DC

- Temperature: 20-22°C

- Time: 30-60 minutes

- Thickness: 5-25μm

Type III (Hardcoat) Anodizing

- Electrolyte: 15% H₂SO₄ at 0°C

- Voltage: 24-36V DC

- Current density: 1.5-2.5 A/dm²

- Thickness: 25-100μm

- Hardness: 500-700 HV

Coloring Methods:

- Electrolytic (two-step process)

- Integral (organic acid process)

- Dip dyeing (for Type II)

- Interference coloring (optical effects)

4. Advanced Coating Technologies

A: Powder Coating Innovations

- Superdurable Polyesters: 15+ years outdoor durability

- Fluoropolymer (PVDF): Extreme weather resistance

- Thermally Conductive: For heat sink applications

- Anti-microbial: Hospital and food processing uses

B: Liquid Coating Systems

- 2K Polyurethanes: High chemical resistance

- Waterborne Epoxies: Low VOC option

- UV-Curable: Instant cure, energy efficient

- Ceramic Coatings: Thermal barrier properties

C: Emerging Technologies

- PVD (Physical Vapor Deposition)

- Plasma electrolytic oxidation

- Graphene-enhanced coatings

- Self-healing coatings

Powder coating on carbon fiber

Electropolishing

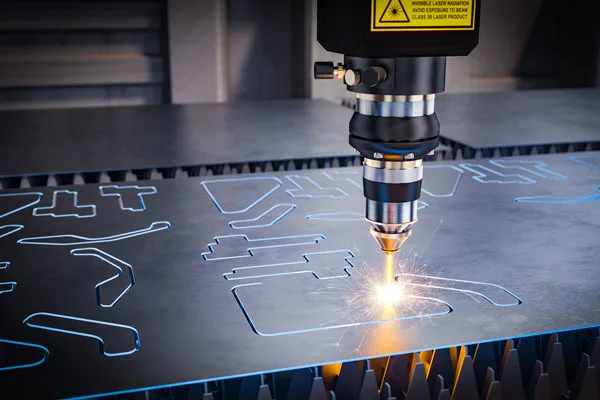

Laser ablation

Selection Guide: Matching Finishes to Applications

|

Application |

Primary Requirement |

Recommended Finish |

Alternative Options |

| Building facadesg | Weather resistance | PVDF powder coating | Anodizing (Type II) |

| Marine hardware | Saltwater resistance | Hardcoat anodizing | Epoxy powder coat |

| Medical devices | Cleanability | Electropolish + passivation | High-gloss powder |

| Consumer electronics | Aesthetics | PVD coating | Precision anodizing |

| Heat sinks | Thermal transfer | Bare aluminum + chemical film | Thin anodizing |

| Food processing | Sanitation | FDA-approved powder | PTFE coating |

Ci64 spectrophotometer

Quality Control and Testing Methods

1. Coating Thickness:

- Magnetic induction (for non-magnetic substrates)

- Eddy current

- Cross-section microscopy

2. Adhesion Testing:

- ASTM D3359 (cross-hatch)

- ASTM D4541 (pull-off)

- Bend tests

3. Corrosion Resistance:

- Salt spray (ASTM B117)

- Humidity testing

- Cyclic corrosion testing

4. Aesthetic Evaluation:

- Color measurement (spectrophotometry)

- Gloss measurement (60° angle)

- Surface roughness (profilometry)

Sustainability in Aluminum Finishing

Modern finishing processes emphasize environmental responsibility:

-

- Waste Reduction: Closed-loop pretreatment systems

- Energy Efficiency: Low-cure powder coatings

- Material Innovation: Chrome-free pretreatments

- Recycling: Anodized aluminum retains 100% recyclability

Future Trends in Aluminum Finishing

Smart Coatings:

- Self-cleaning surfaces

- Thermochromic/piezochromic coatings

- Anti-fingerprint technologies

Digital Finishing:

- Inkjet printed patterns

- Laser coloration

- 3D texture mapping

Advanced Protection:

- Nano-ceramic coatings

- Hybrid organic-inorganic systems

- Molecular-level corrosion inhibitors

Conclusion: Optimizing Your Finishing Strategy

Selecting the proper aluminum extrusion finish requires careful consideration of:

- Performance requirements (environmental exposure, lifespan)

- Functional needs (electrical, thermal, mechanical)

- Aesthetic goals (color, texture, branding)

- Regulatory compliance (RoHS, REACH, FDA)

- Cost parameters (initial vs lifecycle costs)

By understanding the full range of available finishing technologies and their capabilities, engineers and designers can specify solutions that maximize both performance and value. For critical applications, consult with finishing specialists to conduct pre-production testing and develop customized solutions.