A Comprehensive Guide to the Types of 3D Printing

3D printing, also known as Additive Manufacturing (AM), has revolutionized how we design, prototype, and manufacture objects. Unlike traditional subtractive methods that carve out a shape from a block of material, 3D printing builds objects layer by layer from the ground up, directly from a digital file. This technology is not a single, monolithic process. Instead, it’s an umbrella term for a family of distinct technologies, each with its own principles, materials, strengths, and weaknesses. Understanding these different types is key to selecting the right tool for the job. The most common way to categorize these technologies is by the ISO/ASTM 52900 standard, which groups them into seven core categories. We will explore the most prominent ones in detail.

SLA

DLP jewelry

mSLA

1. Vat Polymerization: Curing Resin with Light

This category involves a vat (tank) of liquid photopolymer resin that is cured (solidified) by a focused light source.

Stereolithography (SLA)

- How it Works:A high-powered laser traces the cross-section of a part onto the surface of the liquid resin. Where the laser hits, the resin solidifies. The build platform then lowers, a new layer of resin is swept over the part, and the process repeats.

- Materials:Photopolymer resins (standard, castable, tough, flexible, dental, etc.).

- Strengths:

- Extremely High Resolution and Detail:Produces the smoothest surface finish and finest features of all 3D printing technologies.

- Isotropic Parts:Parts have consistent strength in all directions.

- Weaknesses:

- Brittle Parts:Resin parts are often not as strong or durable as thermoplastic parts.

- Post-Processing Required:Parts must be washed in a solvent to remove excess resin and then “cured” in a UV light chamber to achieve full strength.

- Limited Build Volume:Larger SLA printers can be very expensive.

- Common Applications:High-detail prototypes, dental appliances, jewelry casting patterns, figurines and models.

Digital Light Processing (DLP)

- How it Works:Similar to SLA, but instead of a single laser, DLP uses a digital projector screen to flash a single image of each layer across the entire build platform at once. This makes it faster than SLA for many parts.

- Materials:Photopolymer resins.

- Strengths:

- Faster Print Times:Curing an entire layer simultaneously speeds up the process significantly.

- Weaknesses:

- Slightly Lower Resolution:The resolution is determined by the projector’s pixel size, which can sometimes lead to a “pixelated” effect on curved surfaces (known as voxel lines).

- Common Applications:Similar to SLA, often used in jewelry, dentistry, and detailed prototyping.

LCD Masking (mSLA)

- How it Works:This is the technology behind most affordable desktop resin printers. It functions similarly to DLP, but uses an array of UV LEDs shining through a high-resolution LCD screen as the light source. The LCD screen acts as a mask, displaying the layer’s image and blocking UV light where curing is not needed.

- Materials:Photopolymer resins.

- Strengths:

- Very Cost-Effective:LCD screens are cheap, making these printers highly accessible.

- Fast and High-Resolution:Offers speed comparable to DLP at a fraction of the cost.

- Weaknesses:

- LCD Screen Wear:The LCD screen is a consumable item and degrades over time, requiring replacement.

- Common Applications:Hobbyist printing, miniatures, small detailed parts.

2. Material Extrusion: The Familiar Fused Deposition

This is the most common and affordable type of 3D printing, popularized by many consumer-grade machines.

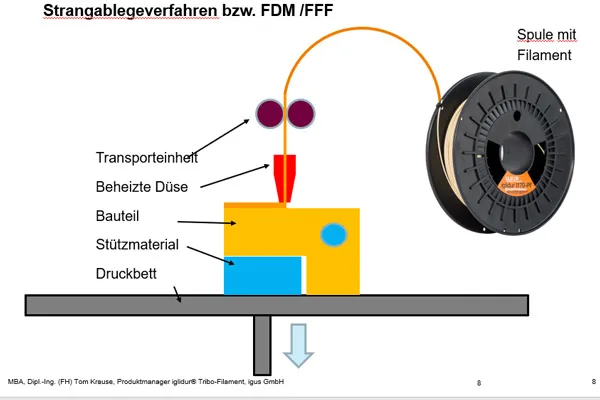

a. Fused Deposition Modeling (FDM) / Fused Filament Fabrication (FFF)

- How it Works:A solid thermoplastic filament is fed through a heated nozzle, where it is melted. The nozzle deposits the melted material layer-by-layer onto a build platform, where it immediately cools and solidifies.

- Materials:A wide variety of thermoplastics, including PLA (easy to use), ABS (strong and durable), PETG (durable and chemical resistant), TPU (flexible), and advanced composites like carbon fiber or glass-filled filaments.

- Strengths:

- Low Cost:Printers and materials are very affordable.

- Wide Material Selection:Huge range of colors and material properties.

- Simple and Safe:Easy to use and maintain; the process is clean and office-friendly.

- Weaknesses:

- Layer Lines:Parts have visible layer lines and often require post-processing for a smooth finish.

- Anisotropic Strength:Parts are weaker in the direction perpendicular to the layers (they can delaminate).

- Need for Supports:Overhanging features require support structures, which must be removed.

- Common Applications:Basic prototyping, functional parts, jigs and fixtures, hobbyist projects, educational tools.

FDM process

SLS TPU 90A Powder

MJF

DMLM

3. Powder Bed Fusion: Fusing Powder with Energy

This family of technologies uses a thermal energy source (laser or electron beam) to fuse powdered material together in a bed.

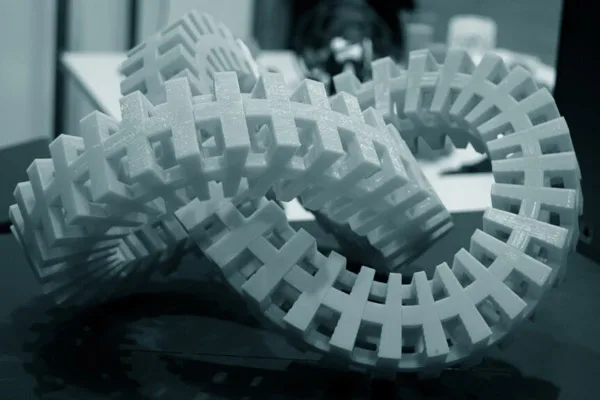

a. Selective Laser Sintering (SLS)

- How it Works:A roller spreads a thin layer of polymer powder over the build platform. A high-power CO2 laser scans the cross-section of the part, sintering (fusing) the powder particles together. The platform lowers, a new layer of powder is applied, and the process repeats. The unsintered powder acts as a natural support structure.

- Materials:Nylon (PA11, PA12), and composites like Alumide (nylon with aluminum dust).

- Strengths:

- No Support Structures Needed:The surrounding powder supports the part during printing.

- Strong and Functional Parts:Produces parts with excellent mechanical properties, often comparable to injection-molded plastics.

- High Complexity:Ideal for complex geometries, interlocking parts, and hinges.

- Weaknesses:

- Rough Surface Finish:Parts have a slightly grainy, sandy texture.

- High Cost:Machines and materials are expensive.

- Porosity:Parts can be somewhat porous.

- Common Applications:Functional prototypes, end-use parts, complex ducting, medical devices.

b. Multi Jet Fusion (MJF)

- How it Works:Developed by HP, this is a competitor to SLS. An inkjet array selectively deposits a fusing agent onto a bed of nylon powder in the shape of the layer. Then, a detailing agent is deposited around the edges to ensure crisp detail. Finally, an infrared energy source passes over the entire bed, fusing the areas where the fusing agent was applied.

- Materials:Primarily Nylon (PA12, PA11).

- Strengths:

- Faster than SLS:The process of fusing an entire layer at once is highly efficient.

- Consistent Mechanical Properties:Produces highly isotropic and uniform parts.

- Weaknesses:

- Limited Material Palette:Currently dominated by nylons.

- Grained Surface Finish:Similar to SLS.

- Common Applications:High-volume production of functional plastic parts.

C. Direct Metal Laser Sintering (DMLS) / Selective Laser Melting (SLM)

- How it Works:This is the metal version of SLS. A laser fully melts metal powder particles together, layer by layer, to create fully dense metal parts. The part is built within a chamber filled with inert gas (like argon) to prevent oxidation.

- Materials:Metal alloys including stainless steel, titanium, aluminum, Inconel, and cobalt chrome.

- Strengths:

- Fully Dense Metal Parts:Creates parts with strength properties equal to or better than traditionally manufactured metal.

- Complex Geometries:Can produce internal channels and lattice structures impossible with machining.

- Weaknesses:

- Extremely High Cost:Machines can cost hundreds of thousands of dollars.

- High Stress:The process induces thermal stresses, so parts often require stress-relief heat treatment.

- Specialized Expertise Required:Operation is complex and requires significant safety measures.

- Common Applications:Aerospace components, medical implants (like spinal cages), lightweight automotive parts, complex heat exchangers.

4. Material Jetting: Printing with Photopolymers

This process operates similarly to a standard 2D inkjet printer.

- How it Works:A print head with hundreds of tiny nozzles jets thousands of droplets of liquid photopolymer resin onto the build platform. The jetted material is immediately cured by a UV light as the print head passes over. Support structures are printed simultaneously from a dissolvable material.

- Materials:Photopolymer resins (rigid, flexible, transparent, high-temperature).

- Strengths:

- Incredibly High Detail and Smooth Finish:Can produce parts with a very high dimensional accuracy.

- Multi-Material and Full-Color Printing:Can jet multiple materials simultaneously to create parts with varying properties (e.g., a rigid part with soft-touch grips) or in full color.

- Weaknesses:

- Very Expensive:Both machines and materials are costly.

- Brittle Parts:Similar to SLA, the photopolymer parts lack the toughness of thermoplastics or metals.

- Common Applications:Full-color prototypes, realistic visual models, medical and anatomical models, investment casting patterns.

5. Binder Jetting: Gluing Powder Together

- How it Works:Similar to SLS, a roller spreads a thin layer of powder (polymer, sand, or metal). Instead of a laser, an inkjet print head moves across the bed, depositing a liquid binding agent to glue the powder particles together in the shape of the layer. The process repeats until the part is complete. The part is then left in a fragile, “green” state and must be post-processed.

- Materials:Sand, metal, or ceramic powders.

- Strengths:

- High Speed:No curing/fusing step during printing makes it very fast.

- No Support Structures:The surrounding powder supports the part.

- Full-Color Printing:For polymer/sand parts, color can be added to the binder.

- Low Cost (for metal):Cheaper than DMLS/SLM for some applications.

- Weaknesses:

- Weak “Green” Parts:Parts are very fragile after printing and require significant post-processing.

- For Metal Parts:Must be infused with a secondary metal (like bronze) in a furnace in a process called sintering, which causes part shrinkage.

- Common Applications:

- Sand:Full-color architectural models, sand casting molds and cores.

- Metal:Non-critical metal parts, decorative objects.

Binder jetting

Conclusion: Choosing the Right Technology

There is no single “best” 3D printing technology. The choice depends entirely on the application’s requirements:

- For a cheap, functional prototype?FDM is likely your best bet.

- For a highly detailed, smooth model?SLA/DLP/mSLA is the winner.

- For a strong, complex, functional plastic part without supports?SLS/MJF is ideal.

- For a full-color model or multi-material part?Look at Material Jetting.

- For a fully dense, high-performance metal component?DMLS/SLM is the solution.

As the technology continues to evolve, the lines between these categories are blurring, with hybrid systems and new materials emerging constantly. However, this foundation provides a clear roadmap for navigating the exciting and diverse world of additive manufacturing.