Design Tips

From design to product, material to finishing, read to know more.

Selecting the Right Rapid Prototyping Method: A Technical Guide to Additive Manufacturing Technologies

Selecting the Right Rapid Prototyping Method: A Technical Guide to Additive Manufacturing TechnologiesRapid prototyping plays a critical role in accelerating the product development cycle, enabling engineers and designers to rapidly produce functional models,...

Five Essential Design Principles for Optimizing Plastic Injection Molding

Five Essential Design Principles for Optimizing Plastic Injection MoldingIntroduction: The Critical Role of Design in Injection Molding Success Plastic injection molding stands as one of the most versatile and widely used manufacturing processes worldwide, responsible...

Vacuum Casting: A Comprehensive Guide for Advanced Prototyping and Low-Volume Production

Vacuum Casting: A Comprehensive Guide for Advanced Prototyping and Low-Volume ProductionMany companies utilize vacuum casting to generate high-fidelity prototypes and industrial-grade parts. It is a rapid and effective method for producing design-validated samples and...

More Tips

&

Guidelines

How to Improve Production & Reduce Mistakes in Plastic Injection Molding

How to Improve Production & Reduce Mistakes in Plastic Injection MoldingMistakes are an inevitable part of the product development journey, but in precision manufacturing like plastic injection...

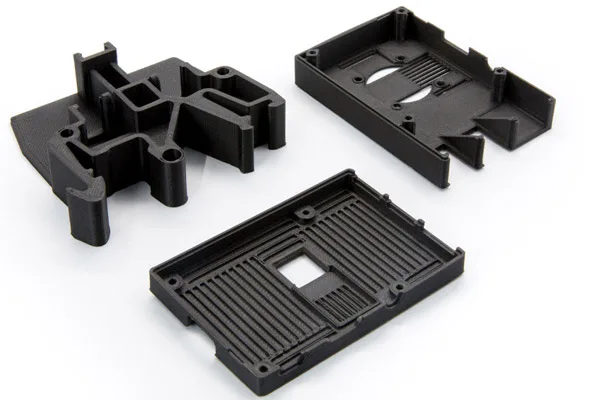

3D-Printed Tooling: Revolutionizing Plastic Injection Molding from Prototype to Production

3D-Printed Tooling: Revolutionizing Plastic Injection Molding from Prototype to ProductionFor decades, plastic injection molding reigned supreme as the undisputed champion of high volume, high...

Navigating the Nuances: A Comprehensive Guide to Low-Volume Production

Navigating the Nuances: A Comprehensive Guide to Low-Volume ProductionIn the world of manufacturing, mass production has long been the dominant model, driving down costs for consumer goods through...

A Comprehensive Guide to the Types of 3D Printing

A Comprehensive Guide to the Types of 3D Printing3D printing, also known as Additive Manufacturing (AM), has revolutionized how we design, prototype, and manufacture objects. Unlike traditional...

The Architect’s Blueprint: A Comprehensive Guide to Choosing the Best Materials in Plastic Injection Molding

The Architect's Blueprint: A Comprehensive Guide to Choosing the Best Materials in Plastic Injection MoldingIn the world of product design and manufacturing, plastic injection molding stands as a...

Comprehensive Guide to Aluminum Extrusion Finishes: Enhancing Performance and Aesthetics

Comprehensive Guide to Aluminum Extrusion Finishes: Enhancing Performance and AestheticsIntroduction to Aluminum Extrusion Finishing Aluminum extrusion has become a cornerstone of modern...

Post Processing for Direct Metal Laser Melting (DMLM)

Post Processing for Direct Metal Laser Melting (DMLM)1. Loose Powder Removal In DMLM, the powder that is not fused during the build will remain in loose powder form. The process of removing the...

Design Guidelines for Vacuum Casting

Design Guidelines for Vacuum CastingDesign OpportunitiesVacuum Casting is a very versatile process that has many advantages for designers. Vacuum Casting tooling is flexible silicone that allows...

How to Prevent Injection Molding Flash?

How to Prevent Injection Molding Flash? Flash is a common defect in injection molding, describing the thin layer protruding from the mold parting line or areas around the mold where two...

The Importance of DFM Report for Rapid Tooling

The Importance of DFM Report for Rapid Tooling The Benefits of DFMDesign for Manufacturing (Design for Manufacturability), also known as DFMA (Assembly), is a manufacturing process commonly used...

How to Make a Silicone Mold for Rapid Prototyping

How to Make a Silicone Mold for Rapid Prototyping Rapid prototyping projects prove concepts and prepare the stage for the product to enter the mass manufacturing phase. Silicone molds are a...

Insert Molding Vs Overmolding

Insert Molding Vs Overmolding Overmolding describes a form of injection molding creating components from two or more different materials. Some manufacturers refer to the process as in-mold...

Revolutionizing Silicone Molding: The Power of 3D Printing Technology for Mold-Making

Revolutionizing Silicone Molding: The Power of 3D Printing Technology for Mold-Making 3D printing technology has already begun to change the face of manufacturing as we know it. And one of the...

Considerations when Designing Parts for Aluminum Extrusion

Considerations when Designing Parts for Aluminum Extrusion For many design engineers and product designers, extruded aluminum is the material of choice for products across a wide range of...

The Six Biggest Innovations that Impacts Additive Manufacturing

The Six Biggest Innovations that Impacts Additive Manufacturing Additive manufacturing and 3D printers have changed the way we make things. It's less expensive, more efficient, and is becoming...

Tips for Rapid Prototyping Success

Tips for Rapid Prototyping Success Rapid prototyping has been around for a while, but it's taken off in the last few years. Today, people are using rapid prototyping for everything from creating...

Three Main Benefits of Using LSR Molding

Three Main Benefits of Using LSR Molding Liquid silicone rubber (LSR) molding is a popular manufacturing process that offers many benefits over traditional injection molding. LSR is a two-part...

8 Important Reasons Why You Need Prototypes

8 Important Reasons Why You Need Prototypes There are several steps in building a product before pushing it for mass production. In each stage, the main goal is to have a product for specific...

The Impact of Aluminum Extrusion Process on the Environment

The Impact of Aluminum Extrusion Process on the Environment The industrial revolution might have been ages ago, but we can still feel its impact on the environment. We have pushed the limits, and...

What is Vacuum Casting?

What is Vacuum Casting? IntroductionVacuum Casting is a copying method used to mold thermosetting polyurethane (PU) for fast production of prototypes or end-use products. There are many different...

Design Guidelines for Direct Metal Laser Melting (DMLM)

Design Guidelines for Direct Metal Laser Melting (DMLM) Although additive manufacturing (AM) removes many constraints of conventional manufacturing, it imposes some new constraints of its own....

5 Most Common Resins Used in Plastic Injection Molding

5 Most Common Resins Used in Plastic Injection Molding One of the reasons Plastic Injection Molding is so prevalent among the manufacturing processes is due to it offers a wide range of materials...

Rapid Prototyping with SLA

Rapid Prototyping with SLAWhat is Stereolithography (SLA)Stereolithography(SLA) is the most widely used rapid prototyping technique and it produces the finest surface finish and dimensional accuracy...

Plastic Injection Molding Surface Finishes

Plastic Injection Molding Surface Finishes Plastic injection molded parts can be surface finished from matte to highly polished. The higher requirement on the surface finish of the part, the...

7 Additive Manufacturing Technologies & The Materials

7 Additive Manufacturing Technologies & The Materials Additive Manufacturing (AM) or most commonly known as 3D printing is defined as a process of joining materials layer by layer to form a...

What is Plastic Injection Molding?

What is Plastic Injection Molding? The Basics of Plastic Injection Molding Plastic Injection Molding is a manufacturing method to obtain plastic molded product by injecting molten plastic resin...

What is Rapid Tooling?

What is Rapid Tooling? Rapid Tooling VS Rapid Prototyping Rapid Tooling is any method or technology that enables rapid production of parts, which will function as a tool (primarily die or mold)....

Types of Rapid Tooling

Types of Rapid Tooling The term Rapid Tooling (RT) is literally described as a process that either uses Rapid Prototyping (RP) process to fabricate the mold directly or utilizes a Rapid...