If you need durable and precise enclosures for your electronic devices, vacuum casting offers a reliable solution. This method enables the production of high-quality, custom housings with excellent detail and finish, meeting both aesthetic and protective requirements. Vacuum casting enables the cost-effective creation of complex and low-volume electronic enclosures while maintaining strong mechanical and heat-resistant properties.

Using vacuum casting, you can safeguard delicate electronics with tailored designs that fit your specific needs. The process supports rapid prototyping and small-batch manufacturing, making it ideal for IoT devices, medical instruments, and consumer electronics. With vacuum casting, your enclosures can achieve both the functionality and appearance your products demand.

Choosing vacuum casting means you gain flexibility in material selection and precise replication of intricate parts. This technique also ensures that your electronic components remain protected against environmental factors, such as corrosion and impact. If you want a balance between precision, durability, and cost, vacuum casting is a viable option for your next enclosure project.

Vacuum Casting Process for Electronics Enclosures

Vacuum casting offers precise and reliable production for electronics enclosures, making it particularly suitable for low-volume or prototype runs. It balances speed, accuracy, and material quality, enabling you to create durable, functional housings tailored to device specifications quickly and efficiently.

Overview of Vacuum Casting

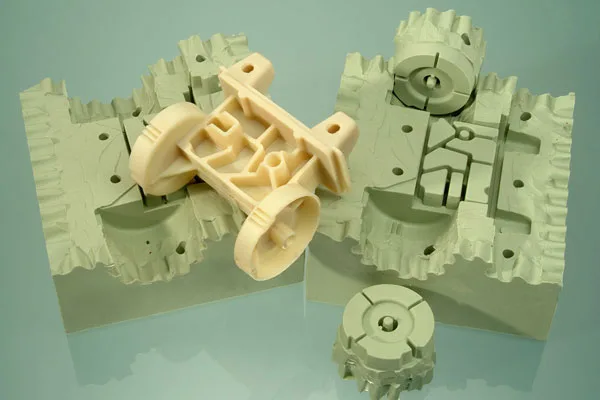

Vacuum casting is a manufacturing process where liquid polyurethane resin is drawn into a silicone mold under vacuum pressure. This method reduces air bubbles, resulting in highly detailed and defect-free parts.

You start with a master model, often created by 3D printing or CNC machining. Silicone molds are made from this master, allowing multiple copies with consistent accuracy. The process is ideal for low-volume electronics housing production, typically up to 20 units, where injection molding is not cost-effective.

This approach achieves a close resemblance to injection-molded parts, making it valuable for functional prototypes and small batch production.

Materials Used in Device Housing

The key materials in vacuum casting are polyurethane resins, chosen for their versatility and performance. You can select from rigid, flexible, or rubber-like variants depending on the device’s needs.

These materials offer high mechanical strength, heat resistance, and chemical stability, which are essential for protecting sensitive electronic components. Some resins also provide anti-corrosion properties, extending the enclosure’s lifespan.

Material properties can be tailored to meet aesthetics, transparency, and durability requirements without costly tooling changes. This flexibility supports the customization and rapid turnaround of device housings.

Benefits of Vacuum Casting for Electronics

Vacuum casting enables the rapid and economical production of detailed, high-quality enclosures. It is particularly suited for low-volume electronics housing production, as it reduces lead times compared to injection molding.

The vacuum environment minimizes air entrapment, improving surface finish and mechanical integrity. You benefit from accurate dimension control and the ability to replicate complex geometries.

This process supports iterative design adjustments without significant retooling costs. Additionally, vacuum casting lets you test fit and function early in development, protecting your investment before scaling up.

Nylon vacuum casting

Step-by-Step Production Workflow

- Master Model Creation

You develop a precise master model, typically through stereolithography (SLA) 3D printing or CNC machining. This part represents the final enclosure design. - Silicone Mold Fabrication

The master is used to produce a soft silicone mold. This mold can create multiple castings with consistent accuracy and fine detail. - Material Preparation

Polyurethane resin is mixed and degassed to remove bubbles, ensuring a smooth cast. - Casting Under Vacuum

The resin is introduced into the mold inside a vacuum chamber. The vacuum pressure pulls the resin to fill every cavity without trapped air. - Curing

The part is cured at room temperature or in an oven, depending on the resin specifications. - Demolding and Finishing

After curing, you remove the enclosure from the mold and perform any necessary finishing, such as trimming or surface treatment.

This workflow lets you achieve rapid, low-volume production while maintaining high precision and material quality.

Applications and Innovations in Electronics Enclosure Prototyping

Vacuum casting enables the creation of precise and durable prototypes suited for various electronic enclosure needs. It supports rapid iteration while maintaining material flexibility and detail accuracy, essential for functional testing and user experience refinement.

Ergonomic Device Housing Prototypes

When designing ergonomic device housings, vacuum casting excels in replicating complex shapes that fit comfortably in the hand. This method allows you to test different contours and surface textures before finalizing the design. The accurate molding process ensures the prototype closely mimics the feel and weight of production materials.

Vacuum casting also helps evaluate thermal management properties and mechanical durability, which are critical in ergonomic devices. By producing high-fidelity models, you can identify and correct design flaws early, improving comfort and usability without significant tooling costs.

Rapid Silicone Molding for Gadgets

Rapid silicone molding via vacuum casting allows quick turnaround for low-volume gadget components. Silicone molds are flexible and reusable, making the process cost-effective for multiple prototypes runs. This technique also supports a wide range of polyurethane resins, which can simulate various final product materials.

You gain the ability to test mechanical strength, flexibility, and aesthetics in a fraction of the time required by traditional injection molding. Vacuum casting is ideal for small batches of customized parts, particularly for iteration cycles or pre-production demonstrations.

Consumer Product Prototype Casting

For consumer electronics, vacuum casting delivers prototypes with excellent surface finish and dimensional accuracy. This capability is essential when validating designs intended for mass production. Your prototypes can accurately replicate color, gloss, and mechanical properties, providing stakeholders with a realistic preview of the final product.

Vacuum casting is particularly valuable for producing enclosures and housings that require precise tolerances and intricate functional details. You can leverage this technique to evaluate assembly methods, component fit, and the overall robustness of the product.

Vacuum Cast Ergonomic Designs

Vacuum cast ergonomic designs combine precision molding with material versatility to produce prototypes that balance form and function. You can create lightweight yet durable parts that reflect actual use conditions, such as grip pressure and finger placement.

This approach is efficient for ergonomically sensitive electronics, such as handheld devices and wearable technology. Vacuum casting supports quick material changes, allowing you to test various textures and hardness levels to optimize comfort and performance.

Request a quote for your electronics enclosure prototype production at niceandrapid.com.