For centuries, the fundamental principle of compression molding—heating a material and shaping it under pressure—has been a cornerstone of manufacturing. But to see it today as a simple, old-school trick is to miss a revolution. We have entered a new era of compression molding, one in which it is no longer just about making rubber gaskets or plastic plates. It has evolved into a sophisticated, high-precision process that is fundamentally building the structural backbone of our modern technological world.

This renaissance is driven by a powerful convergence: the arrival of advanced composite materials and the demand for complex, strong and lightweight components across industries such as aerospace, automotive and electronics.

Why Compression Molding is Synonymous with High-Performance

The fundamental process – placing a charge of material into a heated die and compressing it into shape – is inherently suited to strength and integrity.

Superior strength: The low pressure flow minimizes fiber breakage in the composite, unlike the high shear forces of injection molding. This preserves the mechanical properties of reinforcing fibers (glass, carbon), resulting in parts with exceptional strength-to-weight ratios.

Exceptional structural integrity: This process produces parts with low internal stresses and minimal voids, resulting in superior dimensional stability and performance under load.

Massive and complex parts: It can produce very large and thick parts that would be impractical or impossible for other processes, such as entire car body panels or truck fairings.

Material versatility: It can process a wide range of materials, from rubber and thermosets to state-of-the-art continuous fiber composites that cannot be injection molded.

Forging the Future: How Compression Molding Builds Better Components

The true high-performance status of modern compression molding is driven by key advancements:

1. Advanced Material Science:

- Carbon Fiber SMC (CF-SMC): This is a game-changer. By using shredded carbon fiber in Sheet Molding Compound, manufacturers can produce components that are both extremely lightweight and phenomenally strong, rivaling aluminum for a fraction of the weight. This is critical for battery enclosures and aerospace components for electric vehicles.

- Advanced Thermoplastic Composites (GMT, Organosheets): The use of Glass Mat Thermoplastics (GMT) or continuous fiber-reinforced thermoplastic sheets allows for incredibly fast cycle times (under 60 seconds) and high impact resistance. The materials are also recyclable, addressing sustainability.

2. Process Enhancements for Perfection:

- In-Mold Coating (IMC): For exterior automotive parts, a paint layer is injected and bonded during the molding cycle. This eliminates a separate painting step and delivers a flawless Class A surface finish directly from the mold.

- Automation & Robotics: Fully automated cells with robots for charge loading, part extraction and pruning ensure consistent quality, high volume and repeatability essential for automotive and aerospace standards.

- Industry 4.0 integration: Sensors monitor pressure, temperature and flow in real-time. Data analytics optimize processes for zero-defect production, predictive maintenance, and reduced cycle times.

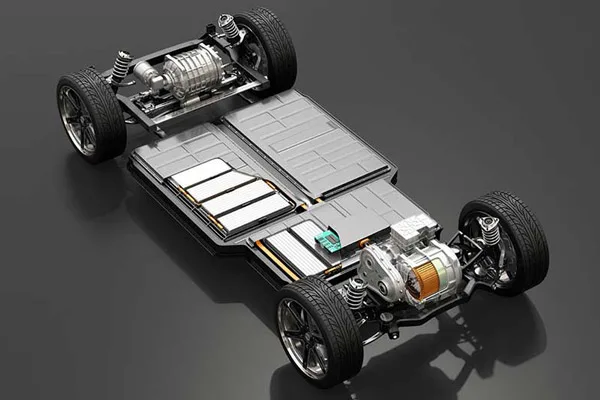

Battery pack motors

High-Performance Applications

Electric Vehicles (EVs):

Structural platforms to house the battery pack are increasingly made from compression-molded SMC. It is also used in battery covers, seat frames and leaf springs to reduce weight and extend driving range.

Aerospace & Aviation:

Interior components such as the sidewalls and luggage bins are compression molded for their lightweight and fire-retardant properties. Even structural components like brackets and ducting rely on the process for its high strength and reliability.

Electronics 5G Infrastructure:

The housings for 5G antennas need to be durable, weather-resistant, and radio-transparent (allowing signals to pass through). Compression-molded composites meet all these requirements perfectly.

Consumer Electronics:

The quest for thinner, lighter, yet durable devices has led to compression-molded components in laptops, tablets, and smartphones, often as internal structural frames or chassis.

Industrial Equipment:

Large, sturdy, and corrosion-resistant covers, housings, and panels for agricultural and construction machinery are efficiently produced via compression molding.

Conclusion

Compression molding is no longer just a plastic shaping process. It is a strategic enabling technology for lightweight and high-strength applications. In the race to build lighter, safer and more efficient vehicles and machines, compression molding provides a critical manufacturing solution that combines the materials science of composites with the precision of advanced process control. It is an indispensable tool for manufacturers who need to push the boundaries of performance.