Manufacturing choices affect your product’s success, cost structure, and market competitiveness. We see this in sheet metal fabrication and 3D printing, which are very different methods of producing parts and assemblies. What you choose between them will, in turn, affect the project timeline, budget, and the quality of the end product.

Both manufacturing methods offer distinct advantages depending on your specific requirements. Understanding the strengths and limitations of sheet metal fabrication versus 3D printing helps you make informed decisions that optimize your project outcomes.

Sheet Metal Fabrication Advantages for Production Manufacturing

Sheet metal fabrication delivers exceptional strength-to-weight ratios that 3D printing cannot match. Metal materials provide superior mechanical properties, including tensile strength, fatigue resistance, and impact durability. Your products benefit from proven material properties and extensive engineering data.

Production volume economics favor sheet metal fabrication for larger quantities. Setup costs amortize across multiple parts, reducing per-unit expenses significantly. Sheet metal processes like stamping and forming become cost-effective at higher volumes, whereas 3D printing remains expensive.

Surface finish quality from sheet metal fabrication meets demanding aesthetic and functional requirements. Professional finishing techniques create smooth, consistent surfaces without visible layer lines. Sheet metal parts often require minimal post-processing to achieve final specifications.

Assembly compatibility makes sheet metal fabrication ideal for complex products with multiple components. Standard fasteners, welding, and joining techniques work seamlessly with metal parts, and sheet metal assemblies integrate easily with existing manufacturing processes and supply chains.

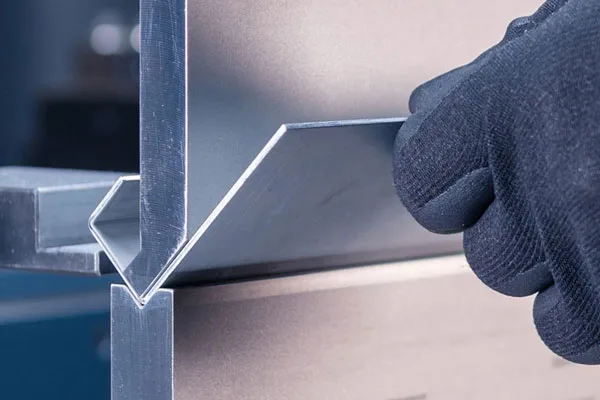

Manufacturing speed advantages emerge in sheet metal production environments. Established processes like laser cutting, punching, and bending complete parts rapidly once setup is complete. Sheet Metal fabrication scales production speed effectively for commercial quantities.

Sheet Metal Bending

Key sheet metal benefits include:

- Superior mechanical properties and material strength

- Cost-effective production for medium to high volumes

- Excellent surface finish and dimensional accuracy

- Compatible with standard assembly and joining methods

- Proven manufacturing processes with predictable outcomes

- Wide material selection, including specialized alloys

3D Printing Strengths for Prototyping and Complex Geometries

3D printing excels at creating complex internal geometries, which is impossible with traditional sheet metal fabrication. Hollow structures, internal channels, and intricate lattice patterns can be manufactured without assembly. Your design freedom increases dramatically with additive manufacturing capabilities.

Prototyping speed gives 3D printing significant advantages over sheet metal fabrication for development projects. Parts can be produced directly from digital files within hours without tooling or setup requirements. Design iteration cycles accelerate when physical prototypes are readily available.

3D printing makes low-volume production economical, whereas sheet metal fabrication requires expensive tooling. Single parts or small batches cost the same per unit regardless of quantity. 3D printing eliminates minimum order quantities that make sheet metal fabrication uneconomical for small runs.

Customization capabilities allow each 3D-printed part to be unique without additional costs. Mass customization becomes feasible where sheet metal fabrication would require individual tooling for each variation. Personalized products benefit from 3D printing’s digital manufacturing approach.

Material variety continues expanding in 3D printing with new polymers, composites, and metal powders. Specialized materials for specific applications compete with traditional sheet metal options. Multi-material printing produces components that exhibit different characteristics across their entire structure.

Cost Analysis: Sheet Metal vs 3D Printing Economics

Initial setup costs differ dramatically between sheet metal fabrication and 3D printing. Sheet metal processes require tooling, fixtures, and programming, creating upfront expenses. 3D printing eliminates tooling costs but charges premium materials and machine time prices.

Volume break-even points determine which technology offers better economics. Depending on complexity, sheet metal fabrication becomes cost-effective at quantities typically above 100-500 pieces. 3D printing maintains consistent per-unit costs regardless of volume.

Material costs favor sheet metal fabrication for standard grades and thicknesses. Raw sheet materials cost significantly less than 3D printing powders or filaments per unit weight. Sheet metal waste can be recycled, further reducing material expenses.

Labor requirements vary between the two manufacturing approaches. Sheet metal fabrication requires skilled operators who process multiple parts simultaneously. 3D printing needs minimal operator attention but produces parts sequentially, limiting throughput.

Secondary operations affect total project costs differently. Sheet metal parts may require deburring, finishing, and assembly operations, while 3D-printed parts often need support removal, surface treatment, and post-curing processes.

SLA 3Dprinting parts

Application-Specific Selection Criteria for Sheet Metal and 3D Printing

Structural applications requiring high strength typically favor sheet metal fabrication. Metal’s proven mechanical properties benefit load-bearing components, pressure vessels, and safety-critical parts. Sheet metal provides reliable performance in demanding applications.

Aesthetic products with visible surfaces often choose sheet metal fabrication for superior finish quality. Consumer electronics, appliances, and architectural components require smooth, professional appearances. Sheet metal finishing techniques consistently achieve premium surface quality.

Functional prototypes needing rapid iteration benefit from 3D printing’s speed and flexibility. Design validation, fit testing, and concept demonstration happen faster with additive manufacturing. Sheet metal prototyping requires tooling that slows development cycles.

Depending on specific requirements, low-volume specialized products may favor either technology. Complex geometries and customization push toward 3D printing. Strength requirements and cost sensitivity favor sheet metal fabrication approaches.

Replacement parts and repair applications suit different technologies based on availability and urgency. 3D printing quickly creates obsolete parts when sheet metal tooling is no longer available, and emergency repairs benefit from 3D printing’s rapid response capability.

Decision Framework for Manufacturing Method Selection

Production volume requirements provide the primary decision criteria. Sheet metal fabrication becomes economical at higher volumes, while 3D printing suits low-volume applications. Your expected quantity determines which technology offers better economics.

Geometric complexity significantly influences manufacturing method selection. Simple shapes and standard forms favor sheet metal fabrication, while complex internal features and organic geometries require 3D printing capabilities.

Timeline constraints affect technology choice based on the development stage and production urgency. Sheet metal fabrication requires longer setup times but produces parts faster once running. 3D printing starts immediately but may take longer for large quantities.

Quality requirements, including strength, appearance, and dimensional accuracy, guide selection decisions. Sheet metal fabrication provides superior mechanical properties and surface finish. 3D printing offers design freedom but with material and surface limitations.

Sheet metal fabrication and 3D printing effectively serve specific manufacturing needs. Your project requirements determine which technology delivers optimal results. Understanding both approaches helps you make informed decisions that balance cost, quality, timeline, and performance objectives for successful product development.

Are you looking for reliable sheet metal fabrication services and expert guidance on selecting manufacturing methods? Contact Nice Rapid today to streamline your production process with professional outsourcing solutions.