NICE Rapid Blog

Latest news and knowledge to share.

Aluminum Extrusion Technology in LED Lighting Systems

LED lighting has revolutionized the lighting industry in recent years with its energy efficiency, long life span and versatile design possibilities. A key enabler of these advances is aluminum extrusion technology, which plays a vital role in the development,...

Additive Manufacturing as an Archaeological Tool: Applications in Artifact Reconstruction

Additive Manufacturing (AM), commonly known as 3D printing, has emerged as a transformative technology in archaeology, offering unprecedented capabilities for the documentation, analysis, and reconstruction of cultural heritage. By enabling the creation of accurate...

Vacuum Casting in the Medical Industry: Key Innovations and Applications

Vacuum casting, a proven process for creating high-quality prototypes and small batches, is undergoing significant innovation in the medical sector. Driven by the need for patient-specific solutions, biocompatible materials, and rapid iteration, these advances are...

Top 10 Innovations Revolutionizing Blow Molding Technology

Here are the most impactful advances revolutionizing blow molding manufacturing, ranked by their potential to redefine efficiency, sustainability and design capability. 1. AI & Machine Learning Process Optimization Artificial Intelligence algorithms analyze...

Pressure Die Casting in Healthcare: Enabling Precision, Performance, and Patient Care

Pressure die casting is revolutionizing the healthcare industry by providing high-precision, durable and reliable metal components essential to medical devices. This advanced manufacturing process provides numerous benefits that directly impact patient safety, device...

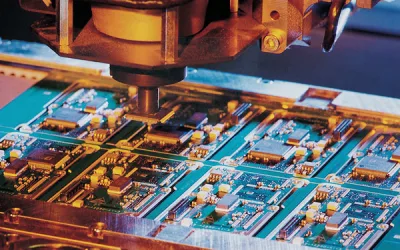

Unseen Precision: How CNC Machining Powers the Semiconductor Industry

The semiconductor industry, the foundation of the digital age, is synonymous with nanoscale engineering, where features on a chip are measured in atoms. It may seem paradoxical, but this world of the infinitesimally small is enabled by a technology that operates on a...

The Application of Plastic Injection Molding in Manufacturing TV Insulating Housings

The sleek, modern form of contemporary televisions belies a complex manufacturing achievement made possible by plastic injection molding. This manufacturing process stands as a cornerstone of television production, particularly in creating the essential insulating...

The Transformative Role of 3D Printing in Medical Devices: From Custom Implants to Bioprinting

3D printing also known as Additive Manufacturing (AM), is one of the most transformative technologies in medical devices. It is moving beyond prototyping to become the core approach for producing customized, complex, and highly effective medical solutions. Key...

Compression Molding: The Manufacturing Standard for Silicone Kitchenware

Compression molding is the dominant manufacturing process for a wide range of high-quality, durable silicone kitchenware. Its properties are perfectly aligned with the material properties of food-grade silicone and the functional requirements of kitchen tools. Why...

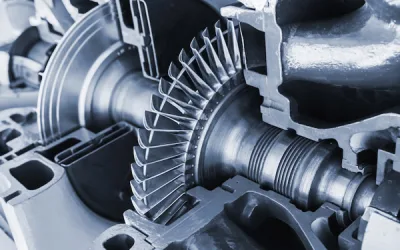

Additive Manufacturing in Aerospace: Applications, Materials, and Future Trends

Additive Manufacturing (AM), commonly known as 3D printing, has evolved from a rapid prototyping tool into a foundational technology reshaping the aerospace industry. Driven by the sector's relentless pursuit of weight reduction, component complexity and supply chain...

The New Era of Personalized Medicine: How Low Volume Manufacturing is Revolutionizing Patient Care

Low volume manufacturing is not just a niche in the medical field; It is a cornerstone of modern healthcare innovation and patient-specific care. The unique demands of the industry - stringent regulations, demand for customization, and high-value, complex components -...

Precision and Comfort: Liquid Silicone Rubber Molding for Dental Solutions

In the exacting world of modern dentistry, the materials and manufacturing processes used have a direct impact on clinical success, laboratory efficiency and most importantly, patient experience. Liquid Silicone Rubber (LSR) injection molding has emerged as a...

Prototype and Manufacturing Services Near By

Rapid Prototyping Services

Turn your ideas into reality fast with our rapid prototyping services. From concept to 3D printing, we bring your vision to life quickly and accurately. Stay ahead of the curve and accelerate your product development process with us.

Silicone Molding

Experience seamless production with our silicone molding expertise. Our precise techniques ensure high-quality, custom molds that bring your designs to life with exceptional detail and durability. Whether you’re crafting prototypes or mass-producing products, our silicone molding services offer efficiency and reliability, empowering you to achieve your goals with confidence.