Multi-layer blow molding is a specialized process used in the pharmaceutical industry to create containers that offer superior barrier properties and product protection. You benefit from enhanced control over material layers, which improves shelf life and maintains the integrity of the drug. This technique enables the combination of different polymers, addressing challenges such as moisture and oxygen permeability.

When you use multi-layer blow molding, you get stronger, safer pharmaceutical packaging without sacrificing design flexibility. Blow molding optimizes your container’s performance by layering materials to achieve specific chemical resistances and mechanical strength. This process is critical when packaging sensitive pharmaceuticals that require strict protection from environmental factors.

Multi-Layer Blow Molding in Pharmaceutical Packaging

You rely on packaging that preserves drug integrity and ensures patient safety. Multi-layer blow molding creates complex structures that combine materials for enhanced protection, durability, and compliance with pharmaceutical standards.

Pharmaceutical Bottle Blow Molding

Pharmaceutical bottle blow molding involves shaping plastic into containers resistant to contamination and chemical interaction. You can design bottles with precise wall thickness and customized shapes, improving dosage accuracy and ease of use.

This process supports the use of high-grade polymers, such as HDPE and PET, which are commonly used in pharmaceutical packaging. You achieve consistent quality and sterile packaging by automating blow molding with stringent process controls.

Barrier Technology in Plastic Bottles

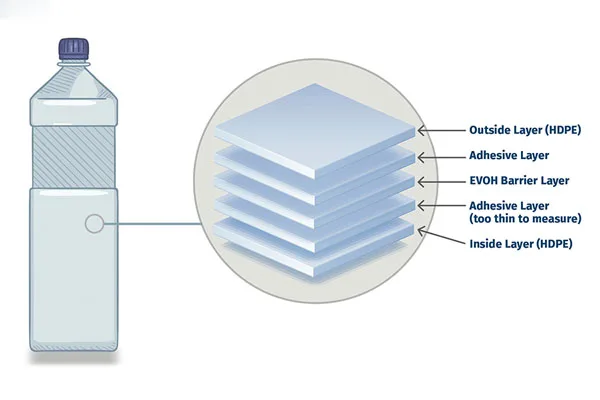

Barrier technology in plastic bottles prevents oxygen, moisture, and light from degrading sensitive drugs. Multi-layer blow molding enables the integration of barrier layers, such as EVOH or PVDC, between polymer layers.

You benefit from increased shelf life and maintained drug efficacy without the need for added preservatives. These barriers also control gas permeability, which is critical for drugs sensitive to oxidation or hydrolysis.

Coextrusion Blow Molding for Drugs

Coextrusion blow molding combines multiple extruded layers simultaneously to form a single, multilayered bottle. You can tailor each layer’s material for specific functions, such as structural strength or barrier performance.

This technology enables you to create containers with complex architectures without requiring additional assembly steps. It is particularly suited for drugs needing advanced protection and traceability in packaging materials.

Mulitlayer bottles

Benefits and Applications of Multi-Layer Blow Molding for Pharma

Multi-layer blow molding enables the creation of complex packaging structures with targeted protective qualities. This technology combines layers with distinct functions, optimizing drug preservation and barrier properties critical to pharmaceutical needs.

Extended Shelf Life Packaging Solutions

Multi-layer blow molding enables the extension of shelf life for pharmaceutical products by incorporating barrier layers that reduce gas and vapor transmission. This limits exposure to oxygen and moisture, which are significant factors in the degradation of drugs.

Using combinations of materials such as polyethylene, EVOH, and nylon, you create packaging that maintains drug potency for more extended periods. The layered design also provides resistance to contamination and mechanical strength, ensuring safe storage and transport.

This packaging reduces the need for preservatives or refrigeration, which can lower costs and simplify logistics. It is particularly valuable for sensitive compounds that require strict environmental control.

Oxygen & Moisture Barrier Bottles

Oxygen and moisture barriers are vital for packaging that protects active pharmaceutical ingredients (APIs) prone to oxidation or hydrolysis. Multi-layer blow molding enables the direct embedding of ultra-thin, high-barrier layers into the container walls.

These bottles prevent the permeability of oxygen and water vapor without compromising container integrity or weight. You can customize barrier properties to match specific drug sensitivities, enhancing product reliability.

The layered construction also allows for transparent or opaque finishes depending on light sensitivity. You get packaging that meets regulatory standards for safety and material compatibility.

Plastic Packaging for Drug Preservation

Multi-layer blow molding enhances drug preservation by combining different polymers that control environmental exposure and prevent degradation. You can design containers that maintain a sterile environment, preventing microbial contamination over time.

The technology permits complex shapes and tamper-evident features for patient safety. It supports lightweight, durable formats that resist physical stress during handling.

Using tailored layer compositions, your containers protect against chemical interactions and maintain formulation stability. This is essential for both liquid and solid drug forms, improving overall efficacy and shelf life.

Visit nicerapid.com to obtain a quote for your project.