For decades, launching a new product meant facing a classic dilemma: the race between speed and scale. You could get a prototype quickly, but transitioning to mass production took months and required a significant investment in tooling. Today, this has changed. A new hybrid approach, which seamlessly blends the speed of additive manufacturing with the power of traditional methods, is helping companies of all sizes get to market faster and with less risk.

This smart integration of technologies shows that 3D printing is no longer just for creating one-off models. It has become a powerful tool that accelerates the entire manufacturing timeline.

From Concept to Prototype in Days

The first and most critical phase of any new product launch is the prototyping phase. This is where a design goes from a digital file to a physical object that can be held, tested, and refined. Previously, this process was slow and costly. It often required machining prototypes from metal or using soft tooling, which could take weeks and cost thousands of dollars for a single part.

Now, 3D printing has completely transformed this step. Engineers can go from a CAD file to a physical prototype in a matter of hours or days. This rapid turnaround enables continuous design iterations, testing of new ideas, and identification of potential flaws long before a costly mistake is made. It shortens the feedback loop, allowing a team to validate a design and move to the next stage in record time.

The Bridge Tooling Strategy

After a design is finalized, a company needs a way to produce a limited number of final parts for market testing or initial sales. This is where “bridge tooling” comes in. Bridge tooling is a temporary production method that bridges the gap between prototyping and full-scale, mass production.

Historically, this involved creating costly, short-run aluminum molds. Today, advanced 3D printing materials enable the creation of functional tooling inserts that can withstand the heat and pressure of an injection molding machine. These inserts are a fraction of the cost of a full steel production mold. This strategy offers key benefits:

- Speed to Market: You can produce market-ready parts in a matter of weeks, not months, outpacing competitors.

- Risk Reduction: Instead of investing hundreds of thousands of dollars in a permanent steel mold, you can use a lower-cost 3D printed tool to test the market’s response to your product.

- Flexibility: If you get user feedback that requires a design change, it is fast and inexpensive to 3D print a new tool. This would be a very costly change with a traditional steel mold.

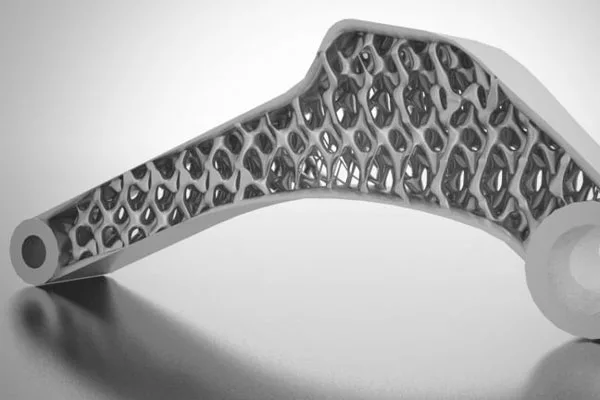

SLS parts

Optimizing Your Product Launch Timeline

This hybrid approach creates a streamlined and efficient product launch timeline:

- Phase 1: Rapid Prototyping – A company utilizes 3D printing to rapidly iterate and finalize the design. This phase might take days or weeks.

- Phase 2: Bridge Tooling for Low-Volume Production: The team utilizes 3D-printed molds to produce the initial run of a few hundred to a few thousand parts. This enables the product to reach early customers quickly. This phase takes a few weeks.

- Phase 3: Hard Tooling for Mass Production: While the bridge tooling is in use, the company can start the longer process of designing and building the permanent, high-volume steel mold. This ensures a seamless transition to mass production once demand is proven. This phase can take several months.

This staged approach is a win for everyone. For a startup, it means a chance to validate a new product without a huge initial investment. For an established company, this means launching a product ahead of its competitors and gathering valuable market feedback before committing to full-scale production.

A Powerful Combination for Modern Manufacturing

The integration of 3D printing into traditional manufacturing is a fundamental change in how products are developed. It is no longer a choice between speed and scale. It is about using the right technology at the right time. By leveraging the speed and flexibility of additive manufacturing for prototyping and bridge tooling, companies can accelerate their time to market, reduce risk, and maintain a competitive edge.

Ready to explore a hybrid approach for your next product launch? As a full-service manufacturing provider, Nice Rapid offers a complete range of services for your next product. We provide solutions that seamlessly integrate both advanced 3D printing and traditional methods, from initial concept to high-volume production. Contact Nice Rapid today to learn how our expertise can help you accelerate your product launch timeline.