In modern electronics and electrical systems, effective thermal management is critical to ensure optimal performance, longevity and safety. Heat sinks and enclosures are essential components designed to dissipate heat and protect sensitive electronic components from overheating. The fabrication of these components requires high precision, complex geometry, and reliable material properties – all expertly achieved through CNC machining. This article explores the crucial role of CNC machining in the production of high-quality heat sinks and enclosures, highlighting technological advancements, design considerations, and future trends in precision heat management.

The Critical Role of Heat Sinks & Enclosures in Thermal Management

As electronic devices become more powerful and miniaturized, managing heat becomes increasingly challenging. Heat sinks facilitate heat transfer away from critical components, preventing thermal runaway and ensuring stable operation. Enclosures, on the other hand, serve to contain and direct airflow, provide physical protection, and sometimes incorporate cooling features.

CNC machining’s ability to produce complex, precise and durable components makes it indispensable for manufacturing these heat management solutions. Accurate fabrication ensures maximum surface area for heat dissipation, proper fit within the assembly and integration of advanced cooling features.

How CNC Machining Enhances Heat Sink & Enclosure Manufacturing

Precision Complex Geometries

- CNC machining allows the creation of intricate fin designs, micro-channels, and surface textures that maximize heat transfer.

- Multi-axis CNC machines can produce complex geometries such as curvilinear fins or internal cooling channels that are difficult or impossible with traditional manufacturing methods.

Material Versatility

- CNC machining supports a wide range of materials suitable for heat sinks and enclosures, including aluminum, copper, magnesium alloys, and advanced composites.

- These materials are chosen based on thermal conductivity, weight, corrosion resistance, and manufacturability.

Tight Tolerances & Surface Finishes

- Precise control over dimensions ensures proper fit and thermal contact with components.

- Surface finishes optimized through CNC processes improve heat transfer efficiency by reducing surface roughness.

Rapid Prototyping & Customization

- CNC machining enables fast iteration of designs, facilitating rapid prototyping.

- Custom thermal solutions can be produced in small batches or as one-off components, ideal for specialized applications.

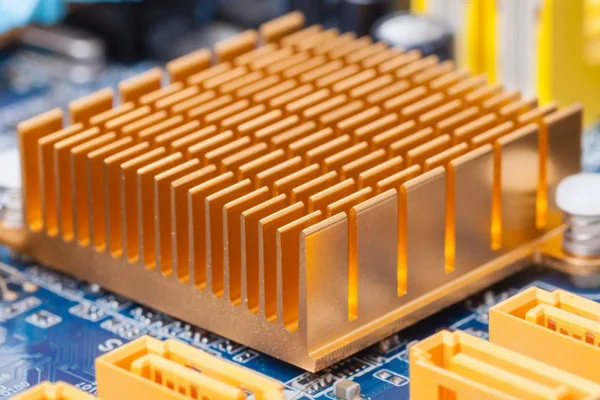

Heat sink

Design Considerations for CNC Machined Heat Sinks & Enclosures

Fin Geometry & Spacing

Fin height, thickness, and spacing directly influence heat dissipation. CNC allows for fine-tuning these parameters for maximum efficiency.

Optimized fin geometry improves airflow and surface area, critical in high-performance applications.

Internal Channels & Features

Incorporation of micro-channels or internal cavities enhances coolant flow and heat transfer.

CNC machining can produce these features with high precision, especially in complex or integrated designs.

Material Selection

Aluminum alloys are popular for their balance of thermal conductivity, weight, and machinability.

Copper offers superior thermal performance but is more challenging to machine and more expensive.

Surface Treatments

Anodizing, coating, or polishing can improve corrosion resistance and enhance thermal performance.

CNC machining offers the flexibility to seamlessly integrate these surface treatments.

Future Trends in CNC Machining for Thermal Management Components

Hybrid Manufacturing Integration

Combining additive manufacturing with CNC machining to produce complex internal cooling channels and lightweight structures with high precision.

Advanced Material Development

Exploration of new composites and high-performance alloys tailored for thermal management, requiring specialized machining techniques.

Micro and Nano-Scale Machining

Increased focus on micro-fin designs and nano-textured surfaces to further improve heat dissipation.

Smart Manufacturing & IoT

Incorporation of sensors and IoT connectivity for real-time monitoring of machining conditions, quality assurance, and adaptive process control.

Sustainability & Eco-Friendly Processes

Using recyclable materials and energy-efficient CNC systems to produce environmentally responsible thermal management solutions.

Applications Across Industries

- Consumer Electronics: Heat sinks for smartphones, laptops, and gaming consoles.

- Aerospace & Defense: Lightweight, high-performance thermal management modules for avionics and military systems.

- Automotive: Cooling solutions for EV batteries and electronic control units.

- Medical Devices: Precise enclosures and heat dissipation components for sensitive medical equipment.

- Industrial Equipment: Durable enclosures and heat exchangers for heavy machinery.

Conclusion

CNC machining plays a critical role in advancing heat management solutions through its ability to produce complex, accurate and reliable heat sinks and enclosures. As electronic systems become more sophisticated and miniaturized, the need for innovative thermal solutions will continue to grow. Leveraging the latest CNC technologies – such as multi-axis machining, hybrid manufacturing and advanced materials – will be essential for creating efficient, durable and customized heat management components. Embracing these innovations will help manufacturers meet the evolving thermal challenges of tomorrow’s high-tech devices, ensuring performance, security and longevity for electronic systems across all industries.