by Nice Rapid | Jan 5, 2026 | Blow Molding

Shin guards are an integral component of protective gear for athletes across a variety of sports, notably soccer, hockey, lacrosse and field hockey. They serve to shield the shin from the blunt impacts, kicks, falls, and collisions that are common in dynamic athletic...

by Nice Rapid | Dec 29, 2025 | Liquid Silicone Rubber Molding

In the evolving landscape of kitchenware and food preparation tools, consumer demand is increasingly shifting toward products that combine safety, durability and aesthetic appeal. Traditional materials such as wood and plastic have served their purpose, but come with...

by Nice Rapid | Dec 22, 2025 | Plastic Injection Molding

In the rapidly evolving world of consumer electronics and personal grooming appliances, the need for high-quality, durable and aesthetically appealing products continues to grow. Among these products, hair dryers stand out as essential grooming tools whose design and...

by Nice Rapid | Dec 19, 2025 | CNC Machining

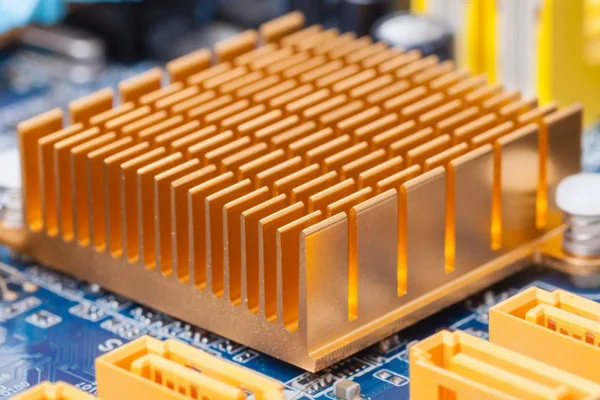

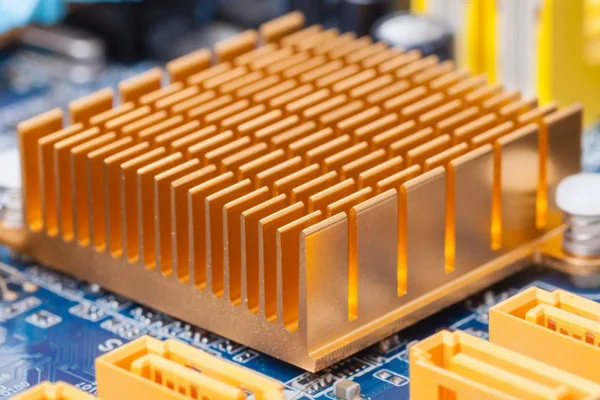

In modern electronics and electrical systems, effective thermal management is critical to ensure optimal performance, longevity and safety. Heat sinks and enclosures are essential components designed to dissipate heat and protect sensitive electronic components from...

by Nice Rapid | Dec 15, 2025 | Sheet Metal

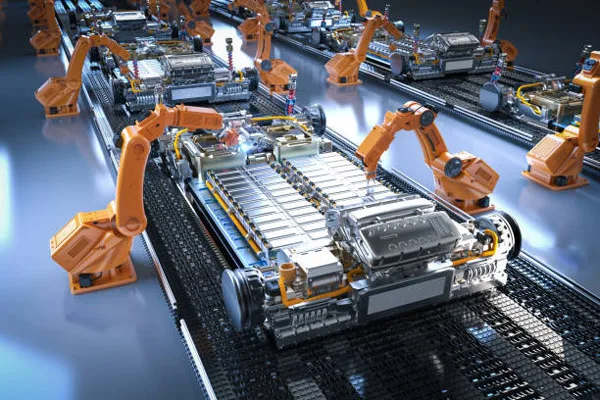

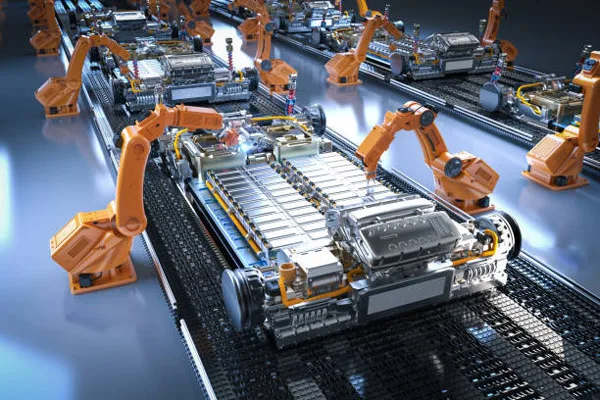

The electric vehicle (EV) industry is rapidly evolving, with manufacturers racing to meet the growing demand for eco-friendly transportation solutions. One key factor driving this revolution is the adoption of green laser cutting technology. In this article, we...