Aluminum Extrusion

Aluminum Extrusion is an important manufacturing process in many industries. We provide customized solution of aluminum extrusion services to meet your company’s specific qualifications, from aluminum extrusion, to surface finish, to machining, cutting and assembly.

Why Use NICE Rapid Aluminum Extrusion Services

Choose NICE Rapid’s auminum extrusion services for precision, efficiency, and reliability in bringing your designs to life. Our expertise in aluminum extrusion enables us to create high-quality, custom aluminum profiles tailored to your specific requirements. Whether you need complex geometries, tight tolerances, or intricate features, our advanced extrusion capabilities deliver consistent results with exceptional accuracy. With a focus on quality and attention to detail, we ensure that every extruded profile meets the highest standards. Trust NICE Rapid for your aluminum extrusion needs and experience the advantages of superior craftsmanship, quick turnaround times, and cost-effective solutions for your projects.

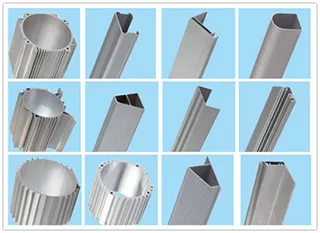

Aluminum Extrusion Profiles

Standard Shapes

This includes common profiles like angles, channels, tees, and bars used in construction and industrial applications.

Custom Profiles

Extrusion allows for the creation of unique shapes tailored to specific needs, including intricate designs and profiles with additional features.

Hollow Profiles

Extrusion can produce hollow profiles such as tubes and pipes, commonly used in structural components and fluid transport systems.

Complex Geometries

Extrusion can achieve complex shapes, including curved profiles and multi-channeled designs, enabling innovative solutions in various industries.

Heat Sinks and Enclosures

Extrusion is used to create heat sinks with specialized fins and enclosures for electronic devices, as well as frames and structural components for machinery and vehicles.

More...

Send your drawings or ideas to us, NICE Rapid can give you a hand on that because we have a comprehensive work system and an excellent supplier management system.

Ready to Start Your Next Project?

Surface Finishing for Aluminum Extursion

NICE Rapid offers a variety of surface finishing options to meet the specific needs and preferences of our customers. Some of the types of surface finishes we can provide include as below table. As a professional Aluminum Extrusion Manufacturing company, we have advanced equipment and technicians that allow us to provide high quality products and best services. Warmly welcome to contact us via enquiry@nice-rapidtooling.com to get free quote if needed.

|

Type |

Description |

Anodization |

This is a special electrochemical finish that can provide additional protection aside from the natural oxide film. And the parts can be colored according to your requirements. |

Mechanical Finishes |

There are series of mechanical finishes such as blasted, polished, sanded and grinded can be improved for surface quality or other cosmetic requirements. |

Powder Coating |

This is also a chemical finish that provide a film to meet stringent performance criteria. The coating is thick and bonds to the aluminum, it doesn’t chip or peel easily. The most important, it has no solvents or VOCs (Volatile Organic Compounds), eco-friendly. |

Sublimation |

This is absolutely a magic experience for some people that see the aluminum extrusion look like wood. Yes, sure it is sublimation that after applying a base coat of powder. And the sublimation process transfers that pattern directly onto the extrusions according to customer’s requires. |

Mirror Surface |

In order to give the aluminum a specular or “mirror” finish, we need to put the profile into a special dip solution (a combination of hot phosphoric and nitric acids). The aluminum parts can be anodized as well. |