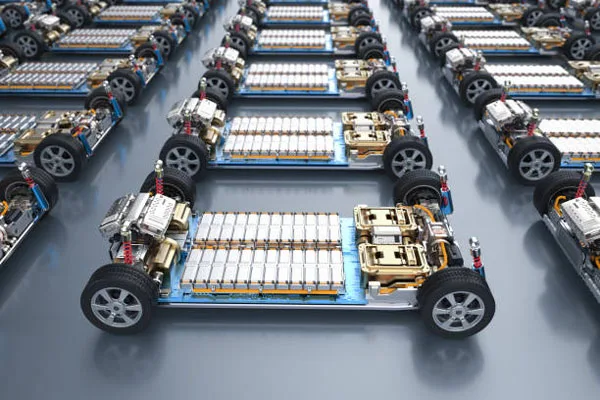

When it comes to EV battery manufacturing, selecting the appropriate die casting process is crucial for both performance and durability. Pressure die casting offers a precise and efficient method for producing battery housings and components that meet stringent quality standards. This method ensures that your EV batteries are both lightweight and strong, thereby improving overall vehicle efficiency and safety.

Your EV battery’s structural integrity depends on tight tolerances and reliable materials, which pressure die casting delivers consistently. This process enables the rapid formation of complex shapes, reducing production time and costs without compromising precision.

Understanding how pressure die casting fits into your battery production can help you optimize design and manufacturing. With advancements in this technology, you can expect enhanced thermal management and better protection for your battery cells.

Fundamentals of EV Battery Die Casting Solutions

You need materials and processes that strike a balance between strength, weight, and manufacturability in EV battery design. Key considerations include the enclosure’s ability to protect battery cells and contribute to overall vehicle efficiency. The following details focus on material choice, production techniques, and performance outcomes.

Lightweight Die Cast Battery Enclosures

Lightweight die cast battery enclosures reduce the total weight of the EV without compromising safety or durability. Utilizing advanced alloys, these enclosures offer high strength-to-weight ratios, which are essential for enhancing driving range and improving energy efficiency.

You benefit from reduced vehicle mass, which directly affects acceleration and braking performance. The casting process ensures consistent wall thickness, which helps in managing thermal expansion and mechanical stresses. You also gain enhanced corrosion resistance when protective coatings are applied after casting.

High-Pressure Die Casting for EVs

Pressure die casting involves injecting molten metal under high pressure into a mold, delivering precision and repeatability crucial in EV battery manufacturing. This process produces components with excellent surface finish and dimensional accuracy, which reduces post-processing costs.

With high-pressure die casting, you can achieve complex geometries necessary for integrated cooling channels or mounting features. The method supports fast production cycles, meeting the high-volume manufacturing demands typical of the EV industry. It also minimizes porosity, improving the mechanical integrity of battery housings.

Aluminum Die Cast Battery Housings

Aluminum is preferred for die cast battery housings due to its lightweight nature and good thermal conductivity. This helps you manage heat generated during battery operation, maintaining safer and more efficient battery performance.

Your aluminum housings also provide strong electromagnetic shielding, protecting battery electronics from interference. The die casting process enables precise dimensional control and complex designs, allowing for the integration of structural and functional elements into a single component. Aluminum’s recyclability further supports sustainability goals in electric vehicle (EV) production.

EV battery

Advanced Manufacturing and Performance Considerations

When working with EV battery die casting solutions, it is essential to address precise thermal control, structural strength, and manufacturing efficiency. These factors directly affect battery safety, performance, and overall vehicle durability.

Thermal Management in Die Cast EV Batteries

Effective thermal management keeps your EV battery within optimal temperature ranges, preventing overheating and ensuring longevity. Pressure die casting enables the integration of intricate cooling channels in battery housings, thereby improving heat dissipation.

You can use aluminum alloys with high thermal conductivity to enhance heat transfer. Designing die cast molds to accommodate liquid or air cooling systems further stabilizes battery temperatures during operation. This avoids thermal hotspots that degrade battery cells or reduce efficiency.

Structural Die Casting for Electric Vehicles

Structural die casting enhances the mechanical integrity of your electric vehicle (EV) battery enclosures and vehicle components. Using pressure die casting, you achieve precise, lightweight parts with high dimensional accuracy and repeatability.

The process supports complex geometries, enabling the incorporation of reinforcement ribs or optimized wall thicknesses that enhance impact resistance. Improvements in the strength-to-weight ratio contribute to enhanced endurance and improved reliability—your battery pack benefits from robust protection without excessive mass.

Die Cast Battery Components Manufacturing

Manufacturing die cast battery components demands tight control over process parameters to ensure quality and consistency. Pressure die casting delivers rapid production with minimal porosity and an excellent surface finish.

You can produce housing covers, terminals, and heat exchangers with unified tolerances. Selecting alloys that offer both corrosion resistance and electrical conductivity is crucial. Automated die casting lines reduce cycle times and lower costs, making your EV battery assembly scalable and reliable.

For accurate quotes tailored to your project, visit nicerapid.com